The three major advantages of electronic wiring harnesses

The three major advantages of electronic wiring harnesses are high reliability, easy installation, and affordability.

In what aspects is the high reliability of electronic wiring harnesses reflected? Electronic wiring harnesses use high-quality materials and advanced production processes, with excellent durability and stability, and can operate stably for a long time in harsh working environments.

What does easy installation of electronic wiring harnesses refer to? The installation process of electronic wiring harness is simple and convenient, without the need for complex tools and techniques, and can be quickly installed and connected.

What are the economic benefits of electronic wiring harnesses reflected in? The manufacturing cost of electronic wiring harnesses is low and the price is relatively low. At the same time, due to its high quality and reliability, it reduces the cost of maintenance and replacement, saving users' economic investment.

Electronic wiring harnesses are suitable for various fields. For example, in the fields of automobiles, electronic devices, communication equipment, household appliances, etc., it is widely used for various electronic and electrical connection needs.

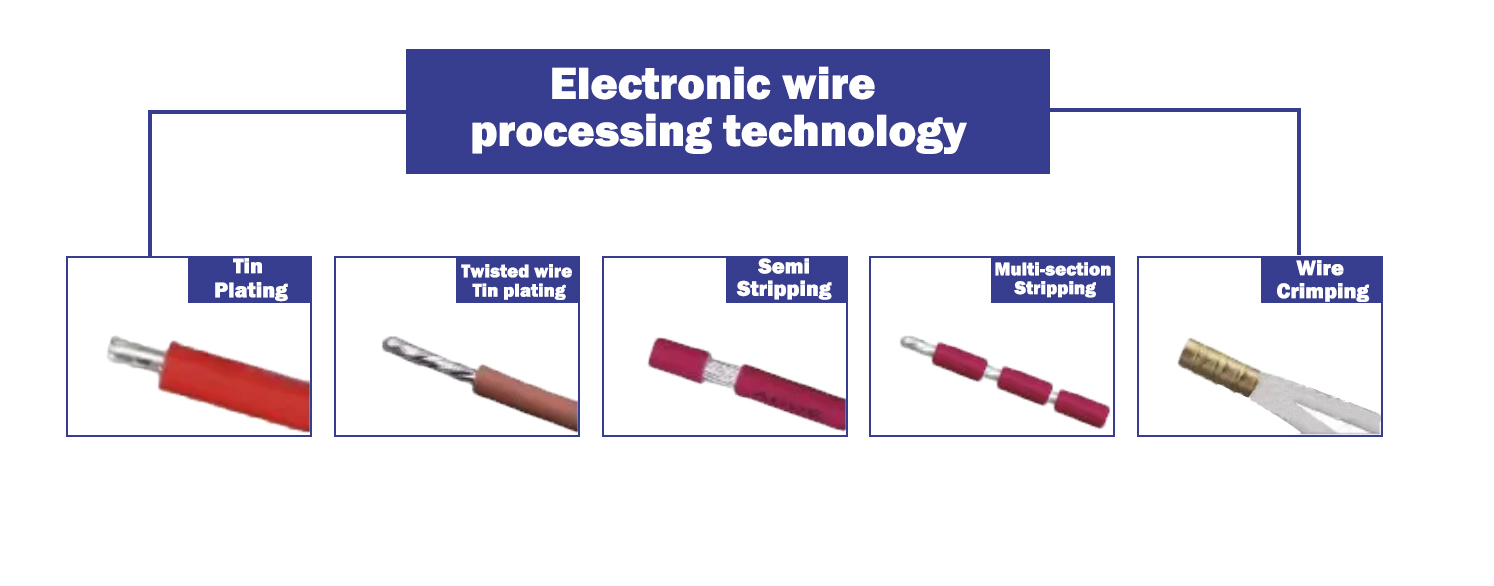

Then there are several main methods for electronic wire processing:

1. Tin stripping on both ends.

2. Tin stripping on twisted wires on both ends.

3. Multi segment stripping.

4. Wire compression.

Recent Posts

2024-12-16 10:01:13

Wiring harness: the link connecting the world

2024-12-10 12:48:04