Analyzing the importance of industrial wiring harness process

In modern industrial production, wire harnesses, as crucial components connecting electronic devices, control systems, sensors and other various parts, their quality and reliability are directly related to the performance and safety of the entire system.

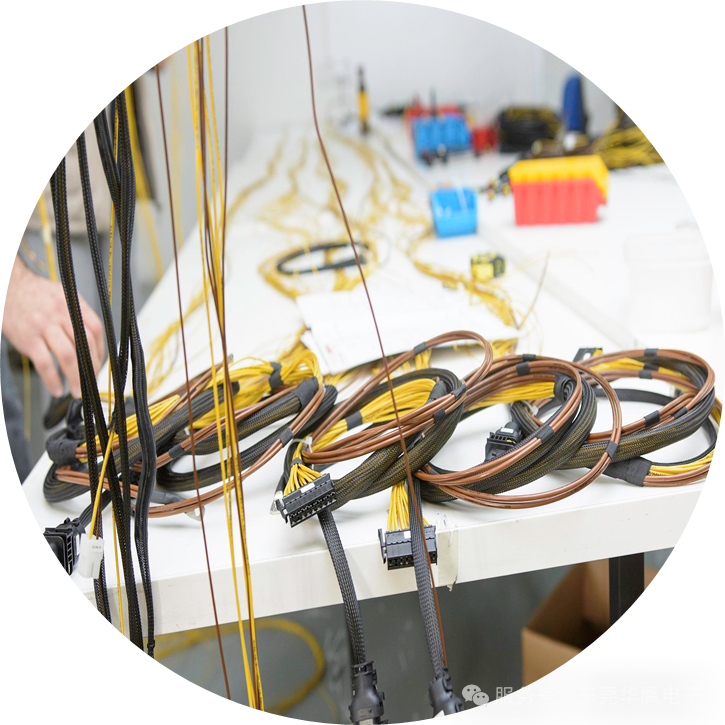

The production of wire harnesses involves a series of elaborate and complex processes. From wire cutting to final packaging, every step is of vital importance.

Therefore, in-depth analysis of the importance of industrial wire harness process not only helps to improve product quality, but also optimizes production efficiency, reduces costs and enhances the market competitiveness of enterprises.

This article will explore this topic from several aspects and elaborate on each key link in wire harness production.

I. Ensuring Product Quality and Reliability

The wire harness process covers multiple steps including wire cutting, stripping, trimming, core wire stripping, tinning, numbering tube insertion, heat shrinking, terminal crimping, soldering and semi-finished product inspection. Each step must strictly follow industry standards and technical specifications to ensure that the electrical performance, mechanical strength and environmental adaptability of the wire harness meet the design requirements. For example, the precision of wire cutting directly affects the smooth progress of subsequent processes and the overall appearance of the wire harness; stripping and trimming are related to the reliability of the contact between conductors and terminals; steps such as core wire stripping, tinning and heat shrinking further enhance the electrical connection stability and anti-environmental interference ability of the wire harness. Correct crimping processes and soldering techniques can ensure good contact between terminals and conductors, reducing signal attenuation and resistance, and improving the stability and efficiency of signal transmission. Therefore, optimizing the wire harness process is the cornerstone of ensuring product quality and reliability.

II. Improving Production Efficiency and Reducing Costs

The high efficiency and cost-effectiveness of wire harness production are equally important. By introducing advanced automated production lines and intelligent management systems, highly automated and customized production of wire harness processing can be achieved. From wire cutting to assembly and then to testing, each step can be precisely controlled, greatly improving production efficiency. Meanwhile, refined management and continuous optimization of the process can reduce material waste, energy consumption and labor costs, thus effectively controlling production costs. For example, automated wire cutting equipment can accurately cut conductors, reducing human errors and waste; intelligent crimping equipment can ensure the accuracy and consistency of each crimping operation, improving production efficiency.

III. Promoting Technological Innovation and Industrial Upgrading

In the face of increasingly complex and changeable market demands, the continuous innovation of wire harness production processes has become the key to promoting industrial upgrading. Through means such as researching and developing new materials, improving production processes and introducing intelligent detection equipment, the performance indicators and manufacturing levels of wire harnesses are continuously improved to meet the market demands for high-performance, lightweight and environmentally friendly wire harnesses. For instance, the research, development and application of new environmentally friendly materials not only improve the environmental performance of wire harnesses, but also reduce production costs; the introduction of intelligent detection equipment can achieve real-time monitoring and feedback of wire harness quality, further improving product quality and production efficiency. In addition, the optimization of the process also promotes the coordinated development of the upstream and downstream industrial chains, drives the technological progress and industrial upgrading of related industries, and injects new vitality into the entire industry.

IV. Assembly, Testing and Packaging

In the later stage of wire harness production, steps such as assembly, label pasting, appearance and function testing, final overall assembly and inspection, and packaging are equally important. The assembly process requires precise combination of various components to ensure the overall performance and aesthetics of the wire harness; label pasting facilitates subsequent maintenance and fault troubleshooting; appearance and function testing is a comprehensive inspection of the wire harness quality to ensure that each wire harness meets the design requirements; the final overall assembly and inspection is a reconfirmation of the overall performance of the wire harness to ensure that the product reaches the best state before leaving the factory; the packaging process is related to the safety of product transportation and storage, and good packaging can protect the wire harness from damage and improve customer satisfaction.

V. Ensuring Safety and Compliance

In fields with high safety requirements such as power, automobiles, and aerospace, the quality of wire harnesses is directly related to personal safety and the stable operation of equipment. Therefore, strictly abiding by national safety standards and industry norms and ensuring that each step of the wire harness process meets safety requirements is an important guarantee for preventing safety accidents such as electrical fires and short-circuit faults. Meanwhile, with the in-depth development of international trade, a process that complies with international standards and environmental regulations is also a necessary condition for enterprises to participate in global competition.

In conclusion, analyzing and optimizing the industrial wire harness process is not only an inherent need for improving product quality and reliability, but also an effective way to improve production efficiency, reduce costs, promote technological innovation and industrial upgrading, and ensure safety and compliance. Facing more intense market competition and technological challenges in the future, enterprises should continue to explore and practice, and constantly promote the innovation and development of wire harness production processes to contribute to the construction of a more intelligent, efficient and safe industrial system.