Wire Harness for Robotics Applications

Wire harnesses play a vital role in the production and manufacturing of robotics; they function like the blood vessels of a robot, forming its neural network. The wire harnesses used in robotics have stringent requirements because most robots operate in special and harsh environments. Therefore, the wire harnesses must possess characteristics such as oil, high and low temperature resistance, dustproof, and waterproof features. Kaweei often customizes the production of wire harnesses specifically for different types of robots.

Applications of Wire Harnesses in Robotics

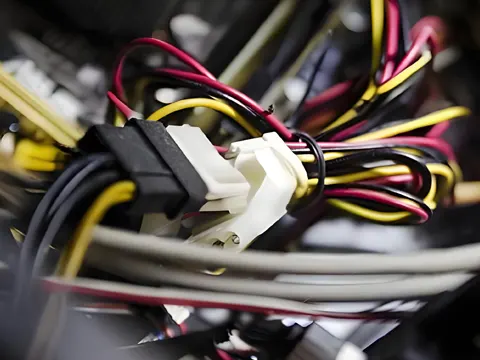

Wire harnesses serve an extremely important function within robots. They comprise the robot’s blood vessels and neural network, transmitting commands and signals among various components. Through these wire harnesses, robots can swiftly convey instructions from the control system to motors, sensors, and other actuation mechanisms. Simultaneously, the harnesses relay the environmental information collected by sensors back to the robot’s control system. Different wire harnesses act as the robot’s nerve fibers, enabling the robot to execute complex coordinated movements and perform tasks effectively.

Additionally, wire harnesses are responsible for transmitting power, providing essential electrical support to ensure the robot operates smoothly. Many robotic working environments demand a stable and efficient power supply, leading to strict requirements for the transmission capability of wire harnesses. In the production process of wire harnesses for robotics, Kaweei conducts tests on the transmission capabilities of various harnesses to ensure their reliability and performance.

High-quality wire harnesses not only ensure the proper functioning of robots but also extend their service life. Given that most robots operate in extremely harsh environments, the demands on their wire harnesses are high. These harnesses need to offer good flexibility, bendability, interference resistance, and corrosion resistance. Through hundreds of experiments, Kaweei has conducted in-depth research and upgrades on wire harnesses designed for robotics, utilizing materials with enhanced interference resistance and adding interference-resistant particles to the outer layer, significantly prolonging the service life of robotics and ensuring their normal operation.

Selecting Wire Harnesses for Different Robotics

Currently, robotics can be primarily divided into industrial robots, commercial robots, and specialized robots. Each type of robot uses wire harnesses that meet different standards. Due to the complex working environment of industrial robots, their wire harnesses should possess good corrosion resistance. Most robots use copper as the core material for wire harnesses because of its superior conductivity and stability. Commercial robots, while operating in better environments than industrial robots, often have strict weight restrictions; hence, they typically choose wire harnesses containing aluminum to effectively reduce their weight. Specialized robots primarily carry out specific tasks and are widely used in military, aerospace, and rescue fields. Most specialized robots do not require weight reduction; therefore, copper is still commonly used as the core material for producing dedicated wire harnesses. In aerospace applications, fiber-optic materials are often used for the wire harnesses to reduce weight while ensuring signal transmission. Different types of robots have varying requirements and standards when selecting wire harnesses, and these should be chosen based on the robot’s operating environment, performance, and production costs.

Kaweei's Robotics Wire Harnesses

Kaweei has strict requirements for the production of wire harnesses used in robotics. All harnesses are usually custom-made, designed according to the application scenarios, surrounding environments, and functional demands of the robots. Details like harness length, color coding, and connector types can be customized according to user specifications. This highly flexible production approach allows for perfect matching of the wire harnesses with the robotic systems.

The wire harnesses produced by Kaweei exhibit high torsional resistance, wear resistance, flexibility, bending resistance, sway stability, and extension properties, ensuring proper functionality during movement and significantly enhancing the robots’ torsional capability. These advantages extend the lifespan of robots utilizing Kaweei harnesses. In addition, Kaweei has optimized robotics wire harnesses and connectors to ensure robust operational capacity in high-frequency, high-vibration, and other demanding environments, minimizing faults and downtime.

Kaweei considers the complex motion requirements of robots, such as resistance to high-frequency bending, waterproofing, oil resistance, wear resistance, high and low-temperature tolerance, aging resistance, and acid-alkali durability. The company continuously optimizes its production processes to ensure that the robotics wire harnesses deliver impressive performance across various application scenarios.

About Kaweei

Kaweei is a seasoned supplier and manufacturer with over 10 years of experience in robotics wire harness production, providing customized production and supply services. Equipped with advanced manufacturing equipment and a skilled technical team, Kaweei produces high-quality, precise robotics wire harness products. The harnesses are widely employed in industries such as manufacturing, telecommunications, automotive, medical, energy, commerce, and rescue. They are tailored to match specific applications, including complex multi-branch harnesses, high-speed data cables, and power distribution components. All robotics wire harnesses meet industry standards such as ISO 9001, IATF 16949, ISO-13485, and IPC/WHMA-A-620, ensuring the best products and services for our clients.