Waterproof Cable Solutions by Kaweei – Reliable Protection in Any Environment

Waterproof cables are specially designed to resist water and moisture. They ensure electrical systems function safely in wet or humid environments. You often encounter these cables in industries like marine communications, oil refineries, and outdoor audio-visual setups. Their construction prevents water from entering electrical components, reducing risks like shocks, fires, or equipment failures. This makes them essential for maintaining safety and reliability in challenging conditions. Whether used in homes or industrial settings, a waterproof cable provides peace of mind by protecting critical systems from moisture damage.

Key Takeaways

- Waterproof cables are essential for safety in wet environments, preventing electrical hazards like shocks and fires by blocking moisture from reaching sensitive components.

- These cables are constructed with advanced materials and sealing mechanisms, ensuring durability and reliability even in harsh conditions, which reduces maintenance needs and costs.

- Common applications include marine communications, outdoor lighting, and industrial settings, where waterproof cables protect critical systems from moisture damage.

- Look for IP ratings like IP67 or IP68 to ensure a cable's waterproof capabilities, especially for underwater or extremely wet conditions.

- Using waterproof cables enhances safety and supports technological advancements in renewable energy and smart systems, contributing to efficient and sustainable operations.

What Are Waterproof Cables?

Definition and Functionality

A waterproof cable is designed to function reliably in environments exposed to water or moisture. Its construction prevents water from penetrating the cable, ensuring uninterrupted performance. These cables use advanced materials like water-blocking tapes, gels, or fillers to enhance insulation and protect internal components. You can rely on them to maintain safety and efficiency in wet or submerged conditions, where regular cables fail.

Key Differences from Regular Cables

Waterproof cables differ significantly from regular cables in both design and functionality. They feature water-tight connectors and multiple layers of protection to block moisture. Unlike regular cables, which lack these features, waterproof cables are built to withstand wet environments. Their specialized construction makes them suitable for marine operations, outdoor installations, and industrial settings. On the other hand, regular cables are not designed for such demanding applications and may fail when exposed to water.

Common Types of Waterproof Cables

Waterproof cables come in various types, each tailored to specific applications. They are categorized based on their level of protection and structural design. Here are some common types:

Submersible Cables

Submersible cables are designed for underwater use. They are ideal for applications like underwater pumps, fountains, and subsea communication systems. Their robust construction ensures they can handle prolonged exposure to water without compromising performance.

Outdoor Waterproof Cables

Outdoor waterproof cables are perfect for environments exposed to rain, snow, or humidity. You’ll find them in landscaping, outdoor lighting, and home security systems. They often feature an HDPE outer sheath for added durability.

Industrial Waterproof Cables

Industrial waterproof cables are built to endure harsh conditions in factories or chemical plants. They often include aluminum-plastic composite tape layers to resist moisture and chemicals. These cables ensure reliable performance in high-humidity or corrosive environments.

Key Features and Benefits of Waterproof Cables

Water-Resistant Materials and Construction

Waterproof cables rely on advanced materials to achieve their water resistance. These materials form a protective barrier that prevents moisture from penetrating the cable. Commonly used materials include:

- Polyvinyl chloride (PVC)

- Polyethylene (PE)

- High-density polyethylene (HDPE)

In addition to these, manufacturers often integrate water-blocking tapes, gels, or fillers into the cable structure. These components enhance the cable's ability to resist water intrusion. Flexible insulating materials like ethylene propylene rubber or cross-linked polyethylene further improve the cable's performance in wet conditions. Waterproof jacket materials, such as PE or PVC, also play a critical role by sealing the cable and ensuring long-term reliability.

Durability and Longevity in Harsh Conditions

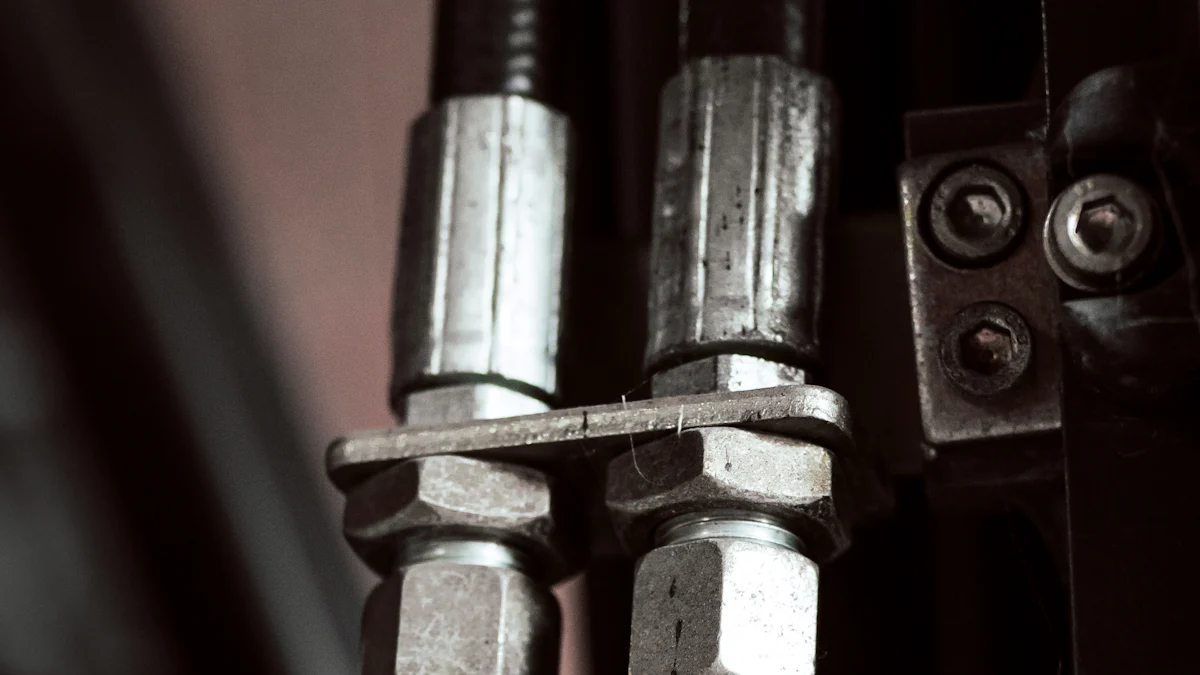

A waterproof cable is built to endure challenging environments. Its robust construction ensures it can withstand prolonged exposure to water, chemicals, and other harsh elements. For example, corrosion-resistant metallic components in connectors prevent damage in wet conditions. Manufacturers test these cables rigorously to confirm their durability. Testing methods include immersing samples in water at elevated temperatures for extended periods and evaluating changes in mass, tensile strength, and elongation. These tests ensure the cable maintains its integrity even after years of use.

Resistance to Environmental Factors

Temperature Extremes

Waterproof cables are designed to perform reliably across a wide range of temperatures. Whether exposed to cold or intense heat, these cables maintain their functionality. This makes them suitable for outdoor and industrial applications where temperature fluctuations are common.

UV and Chemical Resistance

In addition to temperature resistance, waterproof cables can withstand UV radiation and chemical exposure. Their outer sheaths, often made from HDPE or PVC, protect against sunlight and corrosive substances. This feature is especially valuable in outdoor installations and chemical processing plants, where cables face constant exposure to harsh environmental factors.

Safety and Reliability in Wet Environments

Water and electricity can create dangerous situations. In wet environments, you need solutions that prioritize safety and reliability. A waterproof cable provides this assurance by preventing water from reaching electrical components. This design reduces risks like short circuits, electrical shocks, or even fires. You can trust these cables to maintain stable performance, even in the most challenging conditions.

The construction of waterproof cables ensures they meet strict safety standards. Manufacturers use materials that resist water and corrosion. These cables often include sealed connectors, which block moisture from entering the system. This feature is especially important in environments like underwater installations or outdoor setups, where exposure to water is constant.

Reliability is another key benefit. Waterproof cables maintain consistent performance over time. Their durable design minimizes the chances of failure, even when exposed to harsh elements. For example, in marine applications, these cables withstand both water pressure and salt corrosion. In industrial settings, they handle high humidity and chemical exposure without compromising functionality.

Using waterproof cables also reduces maintenance needs. Regular cables may degrade quickly in wet conditions, leading to frequent repairs or replacements. Waterproof cables, however, last longer and require less upkeep. This saves you time and money while ensuring your systems remain operational.

Whether you’re working in a factory, installing outdoor lighting, or managing underwater equipment, waterproof cables offer unmatched safety and reliability. They protect both people and equipment, making them an essential choice for wet environments.

Applications of Waterproof Cables

Marine and Underwater Uses

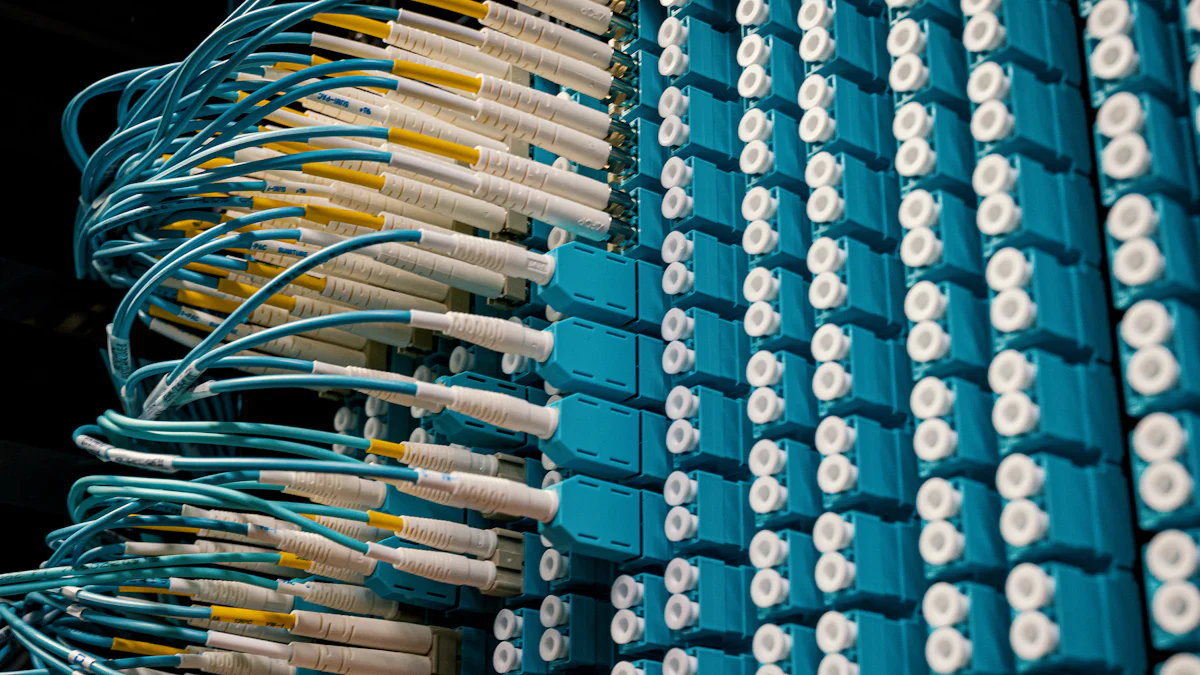

Subsea Communication Systems

Subsea communication systems rely heavily on waterproof cables to maintain uninterrupted data transmission. These cables are designed to withstand immense water pressure and resist corrosion caused by saltwater. For such applications, manufacturers use materials like polyethylene (PE) or polyvinyl chloride (PVC) for the outer sheath. They also incorporate water-blocking tapes and corrosion-resistant metallic components to ensure durability. Specifications for these cables often include gauges ranging from 4/0 to 36 AWG and voltage ratings between 30V and 600V. This robust construction ensures reliable performance in underwater environments, whether for marine communications or shipboard systems.

Offshore Oil and Gas Operations

In offshore oil and gas operations, waterproof cables play a critical role in powering equipment and ensuring safety. These cables are exposed to harsh conditions, including moisture, salt, and extreme temperatures. Their design prevents water intrusion, which could otherwise lead to equipment failure or safety hazards. You’ll find them used in pressure sensor equipment and other systems that require reliable performance in wet environments. Their ability to resist corrosion and maintain functionality makes them indispensable in this sector.

Industrial and Manufacturing Applications

High-Humidity Factories

Factories with high humidity levels, such as food processing plants, depend on waterproof cables to protect their electrical systems. These cables prevent moisture from reaching sensitive components, ensuring uninterrupted operations. Their durability reduces the risk of electrical hazards and extends the lifespan of the equipment. This reliability minimizes downtime and maintenance costs, making them a cost-effective solution for industrial environments.

Chemical Processing Plants

Chemical processing plants often expose cables to both moisture and corrosive substances. Waterproof cables used in these settings feature aluminum-plastic composite tape layers and HDPE outer sheaths to resist chemical damage. This construction ensures the cables can handle the dual challenges of high humidity and chemical exposure. By using these cables, you can maintain safety and efficiency in even the most demanding industrial conditions.

Outdoor and Residential Applications

Landscaping and Outdoor Lighting

Waterproof cables are essential for outdoor lighting and landscaping projects. They protect electrical systems from rain, snow, and humidity, ensuring consistent performance. These cables often feature HDPE outer sheaths for added durability. Whether you’re installing garden lights or powering a fountain, these cables provide a reliable solution for outdoor setups.

Home Security Systems

For home security systems, waterproof cables enhance reliability by preventing water damage and corrosion. They ensure uninterrupted connectivity, even during harsh weather conditions. This is especially important for outdoor cameras and sensors. By using waterproof cables, you can reduce the need for frequent replacements and maintain the effectiveness of your security system over time.

Automotive and Transportation Uses

Electric Vehicles

Waterproof cables play a vital role in electric vehicles (EVs). These vehicles rely on complex electrical systems to power their motors, batteries, and charging components. You need cables that can handle exposure to moisture, especially in rainy or snowy conditions. Waterproof cables ensure the electrical systems in EVs remain safe and efficient, even in wet environments.

Manufacturers design these cables with durable materials like polyethylene (PE) or thermoplastic elastomers (TPE). These materials resist water, chemicals, and temperature changes. For example, the cables used in EV charging stations often feature sealed connectors. These connectors prevent water from entering the system, reducing the risk of short circuits or malfunctions.

Tip: If you own an EV, always check that the charging cables are waterproof. This ensures safe and reliable charging, even during bad weather.

Waterproof cables also improve the longevity of EV components. By protecting the electrical system from moisture damage, these cables reduce the need for frequent repairs. This makes them a cost-effective solution for both manufacturers and vehicle owners.

Public Transportation Systems

Public transportation systems, such as buses, trains, and subways, depend on waterproof cables for reliable operation. These systems often operate in outdoor or underground environments where exposure to water is unavoidable. You’ll find waterproof cables used in lighting, communication, and power systems within these vehicles.

For instance, subway systems require cables that can withstand high humidity and occasional water leaks. Waterproof cables ensure uninterrupted power supply and communication, even in these challenging conditions. Their robust construction prevents corrosion and maintains performance over time.

In buses and trains, waterproof cables connect critical systems like air conditioning, lighting, and passenger information displays. These cables ensure these systems function properly, regardless of weather conditions. This enhances passenger safety and comfort.

Note: Using waterproof cables in public transportation reduces maintenance costs and minimizes service disruptions. This keeps the system running smoothly for passengers like you.

By choosing waterproof cables, transportation providers can ensure safety, reliability, and efficiency in their operations. Whether in EVs or public transit, these cables are essential for modern mobility.

Why Waterproof Cables Are Essential

Ensuring Safety in Hazardous Conditions

Waterproof cables are vital for maintaining safety in environments where water and electricity coexist. These cables feature sealing mechanisms that prevent water from entering connection points. This ensures reliable electrical connections, even in extreme weather. Durable housing materials protect the cables from environmental factors, extending their lifespan. You’ll also find waterproof cable glands that block moisture and dust, reducing the risk of electrical failures. These glands use corrosion-resistant materials, making them suitable for harsh conditions. They maintain their sealing performance across temperature changes, ensuring consistent reliability.

In hazardous environments, such as chemical plants or underwater installations, these cables simplify installation and maintenance. Their robust design allows for easy connections, even in wet conditions. By using waterproof cables, you can reduce the likelihood of electrical hazards like short circuits or shocks. This makes them an essential choice for ensuring safety in challenging settings.

Supporting Technological Advancements

Waterproof cables play a crucial role in advancing modern technology. Innovations in high-performance polymers and elastomers enhance their water resistance and mechanical strength. These materials make the cables ideal for harsh conditions. Smart technology integration has also improved their functionality. For example, sensors embedded in cable joints monitor temperature, humidity, and pressure in real-time. This feature boosts operational efficiency and reduces the risk of system failures.

The growth of renewable energy applications further highlights the importance of waterproof cables. Solar and wind energy installations require durable electrical connections to withstand outdoor conditions. Waterproof cables meet this demand by providing reliable performance in these environments. By supporting these advancements, these cables contribute to the development of sustainable and efficient technologies.

Reducing Maintenance Costs and Downtime

Waterproof cables minimize maintenance needs and reduce downtime in industrial operations. Their IP67/IP68 ratings protect against water ingress, ensuring reliable performance in harsh environments. This durability makes them a preferred choice across industries. You can rely on these cables to prevent moisture from disrupting system functions. Their robust sealing mechanisms shield control electronics from water exposure, enhancing safety and reliability.

Waterproof connector cables significantly lower the risk of electrical malfunctions caused by moisture. Their enhanced durability and resistance to leaks extend the lifespan of your systems. This reduces repair costs and ensures uninterrupted operations.

By using waterproof cables, you can avoid frequent replacements and costly repairs. Their reliability and durability make them a cost-effective solution for maintaining efficiency in industrial and outdoor applications.

Waterproof cables ensure safety and reliability in environments exposed to water, moisture, or dust. Their water-tight connectors protect electrical systems from damage, minimizing risks like shocks or malfunctions. You’ll find these cables essential in industries such as telecommunications, renewable energy, and transportation. Their durable materials and specialized construction resist corrosion and environmental factors, ensuring long-term performance. By using waterproof cables, you safeguard critical systems and reduce maintenance needs. Whether in marine communications or industrial automation, these cables play a vital role in supporting modern technology and infrastructure.

Tip: Use cable ties or conduits to protect cables from physical damage and extend their lifespan.