Wire Harnesses for Medical Applications: Ensuring Quality and Reliability | Kaweei

In the current era of booming electronics and informatization, wire harnesses can be regarded as one of the products with the fastest development momentum, extremely large market demand, and outstanding installation convenience in the industry. From household appliances that are widely used in every family, to cutting-edge communication equipment, computers, and their peripheral devices, as well as security protection, solar energy, aircraft manufacturing, automotive industry, and even sophisticated military instruments and equipment, wire harnesses have extensive and in-depth applications.

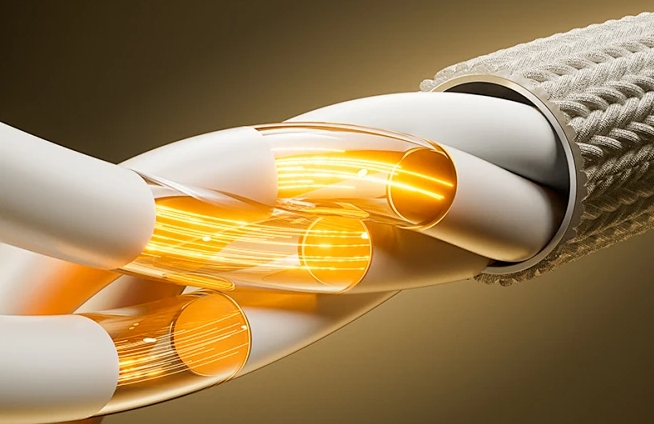

Currently, the wire harnesses we come into contact with are formed by connecting and combining various wires and cables according to specific requirements such as different circuit numbers, hole position numbers, location codes, and electrical principles, with the help of terminals and connectors of different models and performance, along with outer protection devices and adjacent systems, ultimately resulting in a complete wire harness assembly.

According to functional characteristics, wire harnesses mainly fall into the following four categories:

- Firstly, the display driver wire harness, whose core purpose is to provide driving circuit support for various display screens. Virtually all fields involving display screen applications have its presence.

- Secondly, the control wire harness. This type of wire harness mainly undertakes the important task of connecting circuit boards to control the transmission of electrical signals and plays a crucial role in financial equipment, security facilities, new energy vehicles, and medical equipment.

- Thirdly, the power control wire, such as common switch power cords and computer power cords. They control the on-off and distribution of power.

- Fourthly, the data transmission wire, which is mainly responsible for uploading and downloading signals. For example, the connection wires corresponding to HDMI, USB and other series interfaces ensure the high-speed and stable transmission of data.

If classified according to specific application scenarios of products, there are even more types of wire harnesses, roughly including railway locomotive wire harnesses, automotive wire harnesses, wind power generation connection wire harnesses, medical cable, communication wire harnesses, household appliance wire harnesses, industrial control wire harnesses, and so on. Next, let's focus on medical cable.

As the name implies, medical cable are connection wire harness products specifically applied to medical equipment and medical devices. They can be regarded as the "lifeline" of medical electronic equipment. It is no exaggeration to say that without wire harnesses, medical electronic equipment simply cannot operate normally. The wires used are all from high-quality materials that have passed strict certification standards such as UL, VDE, CCC, and JIS. In terms of medical connectors, commonly used ones include wire-to-board connectors, D-SUB connectors, pin headers and female headers, aviation plugs, etc. Moreover, the connector brands selected are mostly international well-known brands such as TE, Molex, and Amphenol. The system certification is usually based on the 13485 medical certification. Given the particularity of the medical industry, most materials also need to meet sterilization requirements. Therefore, for new entrepreneurs who intend to enter this field, it is essential to have an in-depth understanding of the entry barriers and relevant requirements of the medical cable industry. According to a survey report by the research institution BCC Research, the annual growth rate of the global home medical equipment market scale continues to rise, and medical electronics is expected to become a new growth point in the connector application field.

The production process of medical cable is relatively elaborate and complex. First, the electronic wires are precisely cut to the appropriate length according to the drawings. Then, the contact terminals (that is, connectors) made by stamping copper materials are crimped with the wire and cable. Subsequently, insulators are molded on the outside, or metal shells and other protective parts are added. Finally, a component connecting the circuit is formed in the form of wire harness binding. Due to the inherently high-risk and high-precision characteristics of the medical industry, the standards followed by medical devices are significantly different from those of general devices. In terms of the strictness of the standards alone, the inspection standards for medical devices are the strictest.

Ordinary wire harnesses (wire harness), power cords (power cord), FPC, FFC, display driver wire harnesses (LVDS), etc. are widely used in the connection of medical equipment.

Next, let's introduce several wire harnesses unique to the medical industry. They belong to the category of medical consumables and are usually connected and used in conjunction with active medical devices.

ECG Cable: It is composed of several key parts working together, including leads, connectors, cable sheaths, stress relief parts, and shielding shells. These parts perform their respective functions and work closely to accurately transmit the electrical signals generated by the human heart to the electrocardiogram machine, providing a crucial basis for doctors' diagnosis.

SpO2: The blood oxygen saturation probe is a professional instrument for measuring the oxygen concentration in human blood, that is, the blood oxygen saturation. The sensor part is composed of two light-emitting tubes and a phototube. With the help of wires, it can quickly transmit the real-time signals of the oxygen content in the blood to the medical monitor beside the surgical site or the critically ill patient's bed, thus realizing 24-hour uninterrupted monitoring of the patient's blood oxygen saturation changes.

IBP adapter Cable: The disposable invasive blood pressure sensor can immediately transmit the patient's blood pressure signals to the medical monitor used in surgical operations or for critically ill patients through specially made wires, ensuring that medical staff can grasp the dynamic changes of the patient's blood pressure in real-time to take corresponding medical intervention measures promptly.