Wire Harness Connector Guide

Definition of wire harness:

Between two or more isolated electronic circuits to build a communication

The bridge, so that the current can flow, to achieve a variety of electronic elements

device functions, it is a variety of electrical and electronic equipment in an indispensable part.

It is an indispensable part of various electrical and electronic equipment.

the composition of the wire harness:

Ordinary components of the harness is: wire, terminal, plastic.

Complex wiring harness is also added to the composition of: tape, tie, sets of

Tube, sheath, labelling and so on.

Signal harnesses: injection moulding is required.

Photographs of wiring harness products

- Ordinary products

- Complex products

- Signal wire products

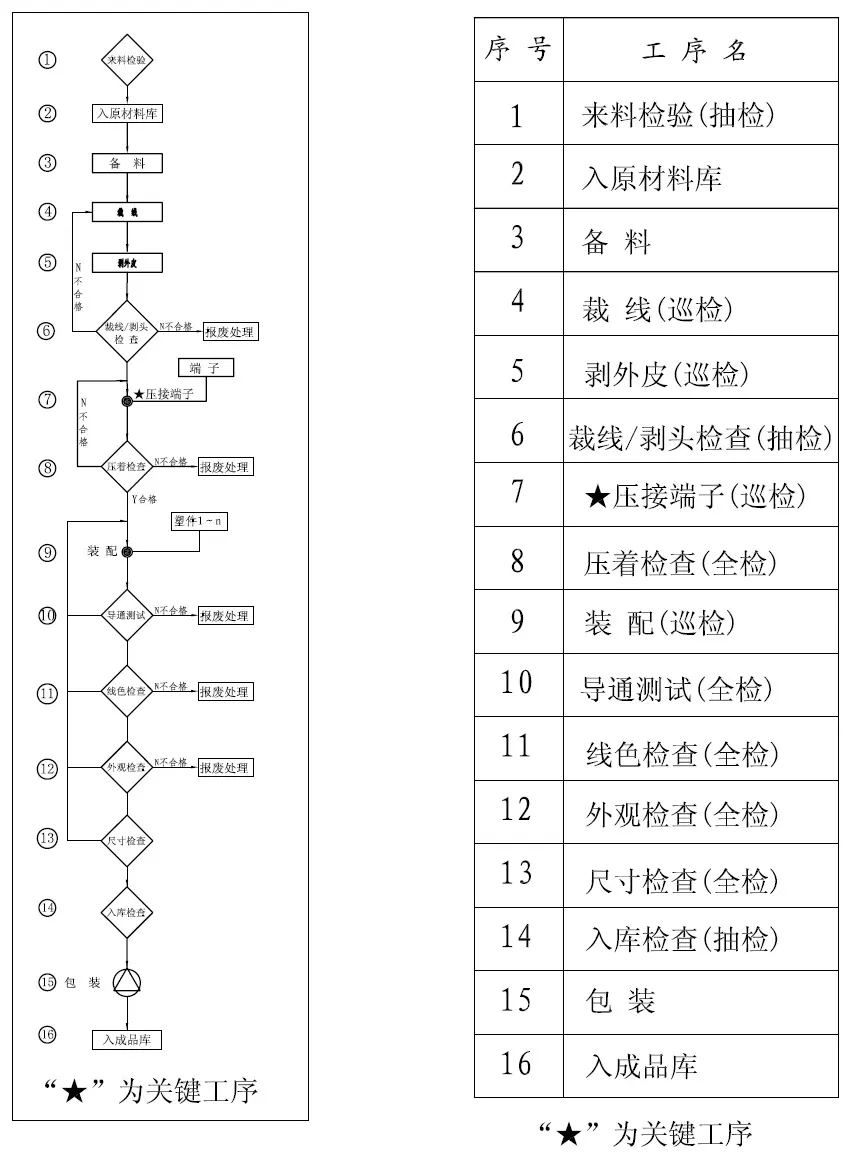

Processing of wire harnesses

I. Cutting process

-Attention points of this process:

1. Confirm the wire specification model, colour;

2. Confirm the length of the lower wire and the length of the stripped head;

3. Confirm that there is no bad phenomenon of the product after the machine operation.

II. crimping process

-1. Definition of crimping

-2. Terminal crimping bad state

-3. The causes and consequences of the defective

-Definition: crimping is a cable assembly process on the wire and terminals for a

Connection method, by applying a certain mechanical force (refers to the stripping of the wire's insulation).

By applying a certain mechanical force (meaning stripping the wire's adiabatic body and pressing the terminal to bite on the conductor), the two materials are closely connected, thus achieving electrical conduction.

by applying a certain mechanical force (meaning the wire is stripped of its insulator and the terminal is pressed against the conductor), so that the two materials are tightly connected, thus achieving the purpose of electrical conduction or a solid joint. Therefore, precise

crimping tools to ensure good crimping quality. Currently, crimping tools

There are manual tools, semi-automatic crimping equipment, fully automatic crimping equipment.

-Function: A good crimp terminal can reduce resistance, reduce the crimp at the copper wire

Oxidation and have a solid tightness and good electrical conductivity and other good properties.

Function. Firm tightness explanation: after tension test in a certain range of

Not to be pulled loose or disconnected.

III. Assembly process

1. Confirm the various materials and semi-finished products to be assembled; (Preparation before work)

2. Confirm the hole number position of the plastic parts;

3. Precautions for assembly.

Recent Posts

2025-04-16 11:04:36

What is a wire-to-board connector?

2025-04-16 09:20:46

How to choose House Electrical Wiring?

2025-04-15 09:27:05