What is the IPC 620 standard?

IPC 620/WHMA-A-620 is an international standard developed by IPC (International Electronics Industry Connection Association) and WHMA (Wire Harness Manufacturers Association) for the requirements and acceptance of cable and harness assemblies.

Here is a brief introduction to the ipc 620 standard:

I. the scope of application

This standard applies to IPC 620 terminal crimping process, covering the terminal type, crimping tools, crimping parameters, crimping sequence, crimping force and other aspects of the requirements. This standard applies to all IPC620 standard terminal crimping occasions, including but not limited to industrial automation, communications, power electronics and other fields.

II. the terminal type and specifications

IPC 620 terminals have a variety of types, including single-hole terminals, multi-hole terminals, plug-in terminals and so on. Each type of terminal has corresponding specification requirements, such as terminal size, shape of contact parts, insulation materials, etc.. Before crimping, you must select the appropriate crimping tools and parameters according to the specific terminal type.

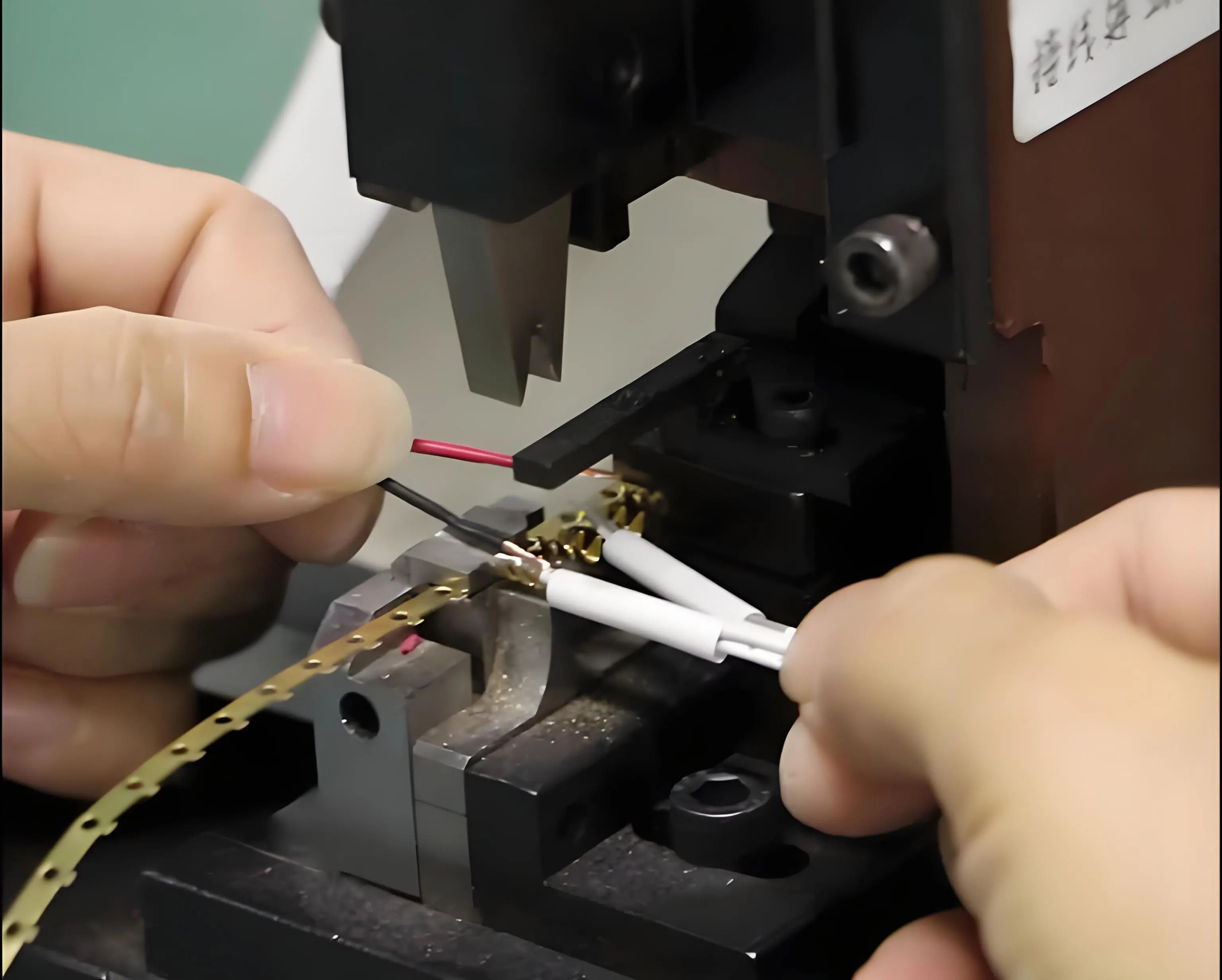

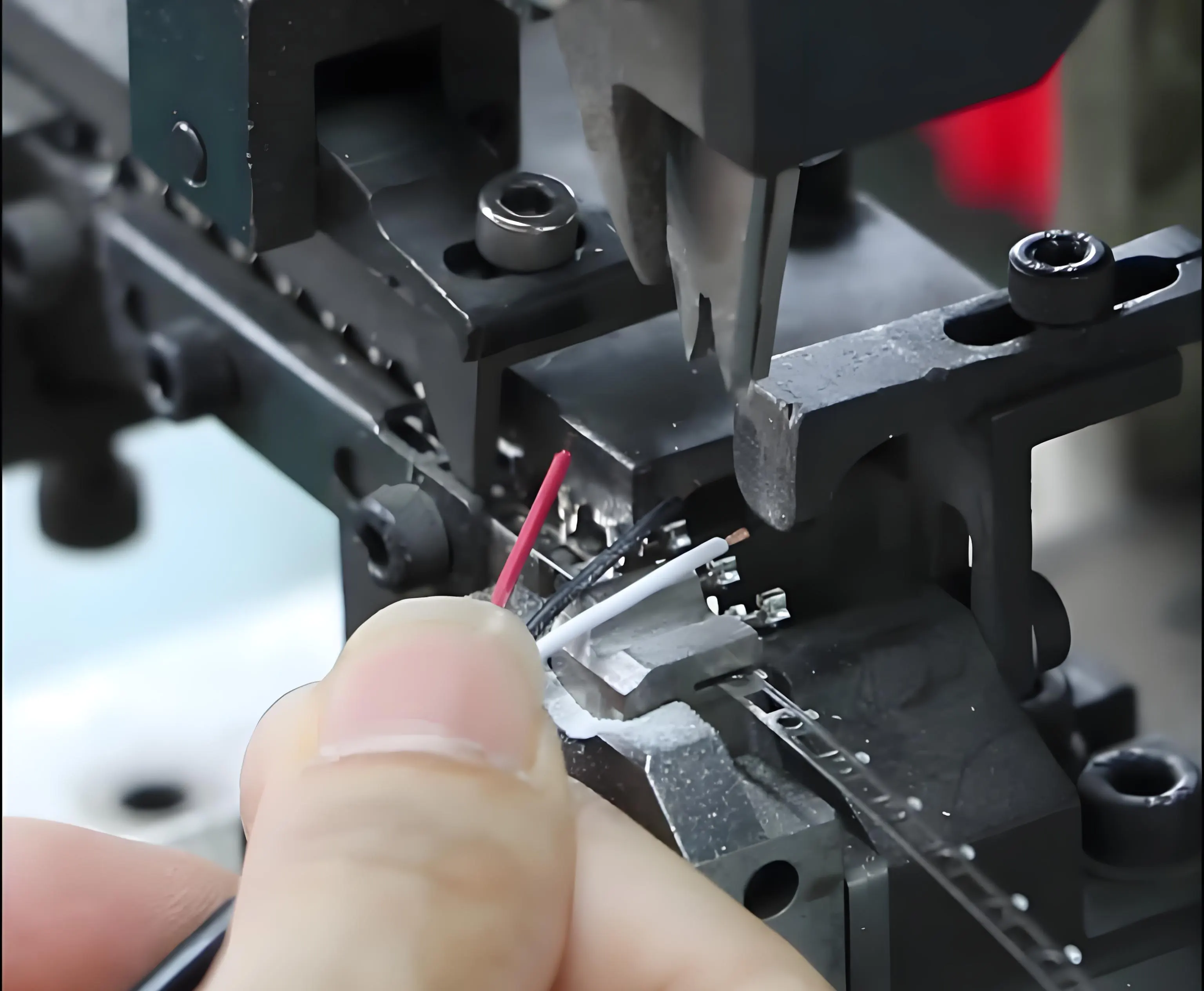

III. crimping tools and equipment

Crimping process requires the use of specialized crimping tools and equipment, including crimping pliers, crimping machines and so on. Crimping tools and equipment selection depends on the type and specifications of the terminal, but also need to consider the requirements of the crimping force. Crimping tools and equipment must be fully tested and verified to ensure that their performance meets IPC 620 standards.

IV. Crimping parameters

Crimping parameters include crimping depth, crimping time, crimping pressure and so on. These parameters must be set according to the type and specification of the terminal to ensure crimping quality. In the crimping process, these parameters must be strictly controlled to avoid overpressure or underpressure, resulting in terminal damage or poor contact.

V. crimping order and operating procedures

In the terminal crimping, must follow certain operating procedures. In general, the first pre-pressure, and then the main pressure. The purpose of the pre-pressure is to make the terminal deformation, the subsequent main pressure to provide sufficient contact area. The main pressure is to restore the deformation generated by the pre-pressure, so that the terminal and the indenter close contact. In the operation process, care needs to be taken to maintain the uniformity and stability of the pressure.

VI. quality testing and evaluation

Crimping is completed, the need for quality testing and assessment. Detection includes the appearance of the terminal, size, resistance value and so on. The test results should meet the requirements of the IPC 620 standard, otherwise rework or scrap processing is required. At the same time, the whole production process also needs to be recorded and analyzed to improve the production process and procedure.

IPC 620 Chinese pdf file(Terminal Crimping Standard)

If you have any related questions, please feel free to contact us at any time. We look forward to hearing from you.

Recent Posts

2025-04-16 11:04:36

What is a wire-to-board connector?

2025-04-16 09:20:46

How to choose House Electrical Wiring?

2025-04-15 09:27:05