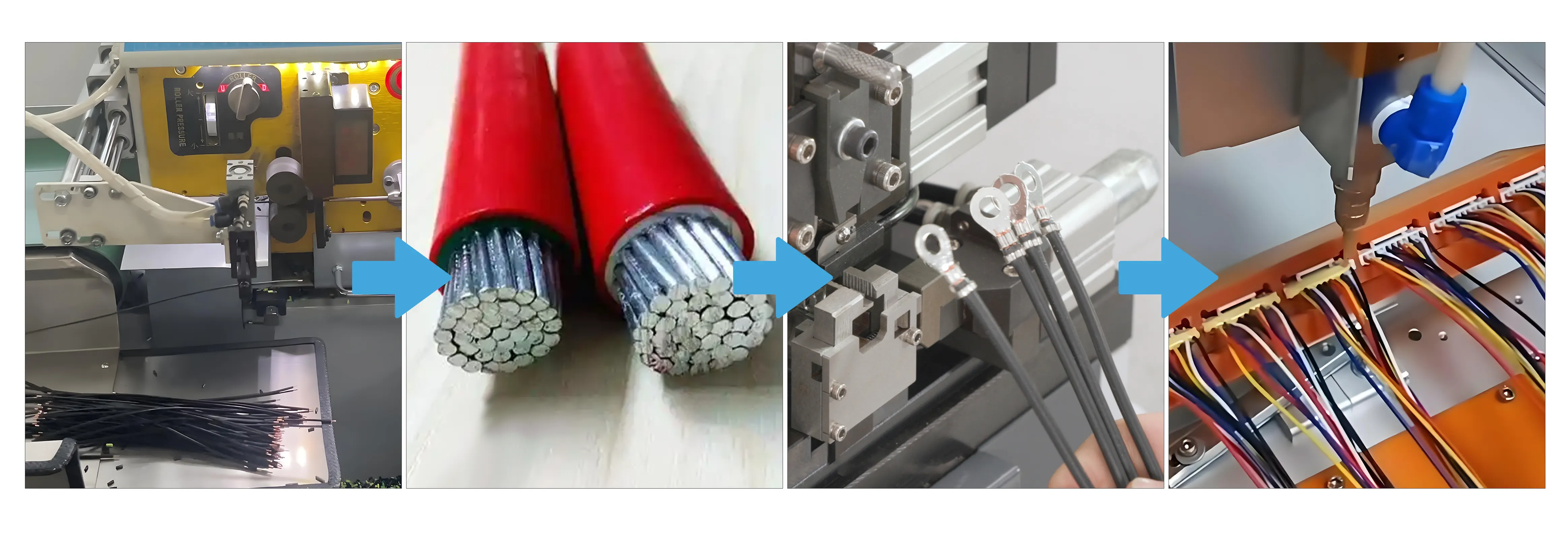

Main processes for wire harnesses

Wiring harness is a composite part composed of wires, cables and connectors, which is widely used in automotive, electronic equipment, aerospace and other fields.

The main production process of wire harness includes wire cutting, insulation removal, terminal crimping, glue injection, assembly and other links.

The first is wire cutting.

Wire is the basic material of the wire harness, according to the design requirements, the wire will be cut into the required length.

The traditional way of wire cutting is manual cutting, but with the development of automation technology, most companies now use automated equipment for wire cutting to improve production efficiency and quality.

Insulation removal is an important step in wire harness production.

The wires are usually wrapped in insulating material, which needs to be removed in order to make subsequent connections.

Common insulation removal methods include mechanical stripping and thermal stripping. Mechanical stripping involves cutting or stripping the insulation with mechanical equipment, while thermal stripping uses heat to melt the insulation and remove it with mechanical equipment.

Terminal crimping is one of the key steps in wire harness production.

By crimping the wires to the connector terminals, the wires are tightly connected to the connectors to ensure current transmission and signal stability.

Terminal crimping is usually carried out using a crimping machine, by setting the appropriate pressure and time, the wire will be firmly connected to the terminal together.

Gluing is one of the important parts of wire harness production.

Gluing can improve the harness waterproof, high temperature resistance and other properties, to protect the wires and connectors. At present, the commonly used injection material has two kinds of hot melt adhesive and frozen adhesive.

Hot melt adhesive is heated to make it melt, and then injected into the wire harness, after cooling to form a gel. Frozen adhesive is cured by freezing at low temperatures.

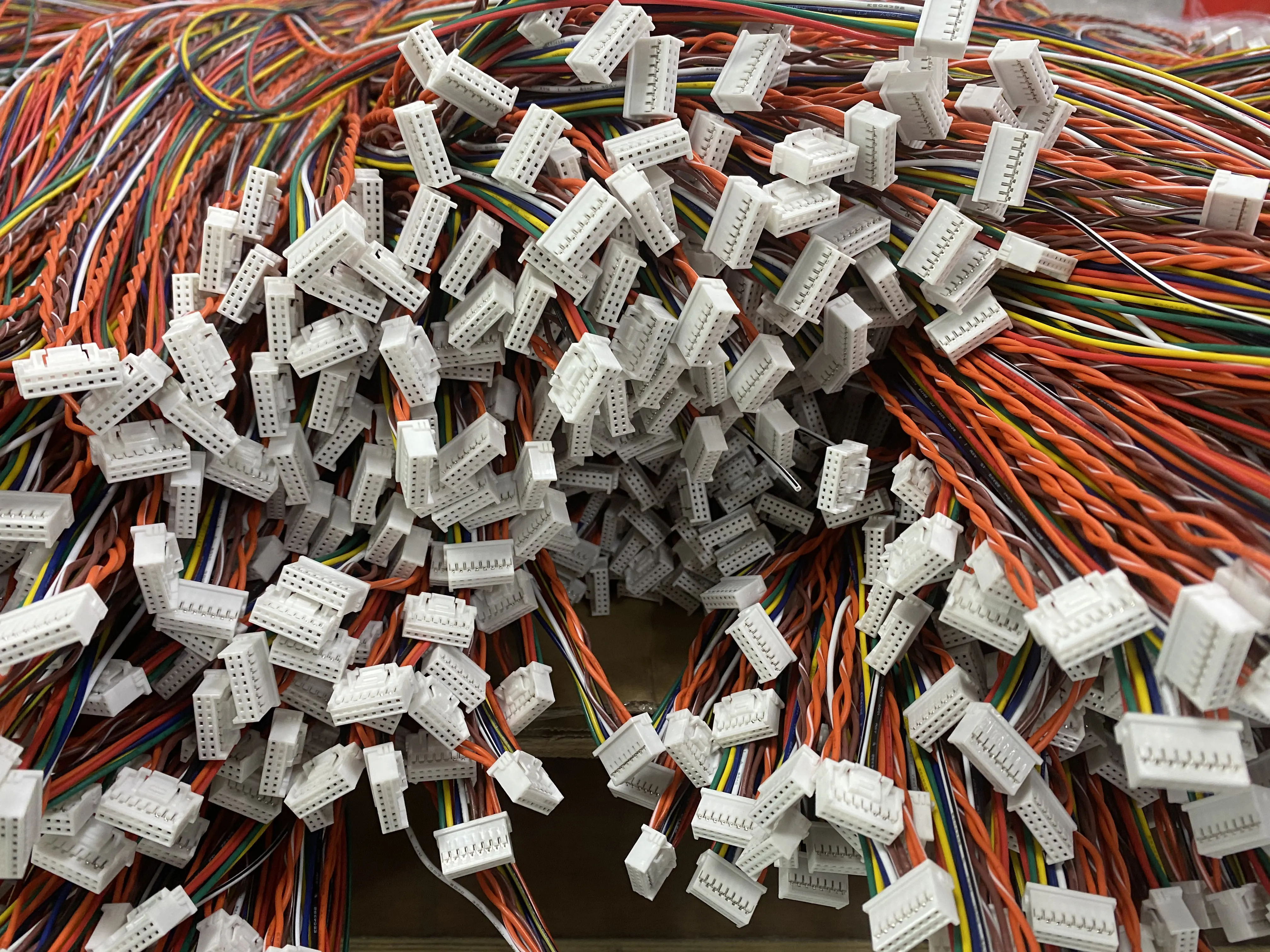

Finally, assembly.

Assembly is the process of assembling the wires, cables, and connectors to form a finished wire harness.

The assembly process usually includes steps such as threading of wires, fixing of connectors and overall packaging. Threading is the wire in accordance with the design requirements through the connector in turn, the connector is fixed to the connector and other parts of the harness is fixed together, usually using adhesives, buttons and other ways.

Finally, the entire harness is packaged to protect the harness from the external environment.

Optimization and innovation of the wiring harness production process is crucial for product quality and production efficiency. As technology advances, more and more automated equipment is being applied to wire harness production, improving production efficiency and consistency.

In addition, the development of new injection materials and connection technology also helps to improve the performance and reliability of the wire harness.

Overall, the production process for wire harnesses involves wire cutting, insulation removal, terminal crimping, glue injection and assembly. By optimizing and innovating these processes, the quality and productivity of wire harnesses can be improved to meet the demand for wire harnesses in different fields.

Recent Posts

2025-04-16 11:04:36

What is a wire-to-board connector?

2025-04-16 09:20:46

How to choose House Electrical Wiring?

2025-04-15 09:27:05