Layout principles of car door wiring harness

Automotive electrical equipment is connected to power sources, control switches, and protective devices through wires. Wires are the basic components that make up the automotive electrical circuit, while wiring harnesses are composed of wires that run in the same direction. Wrapping multiple strands of wires into a harness can prevent the circuit from getting messy, facilitate installation, and protect the wires.

The power supply and various electrical components on the car are physically connected through wiring harnesses, which are distributed throughout the entire vehicle. The car door system is an important collection of functional components, with high requirements for its wiring harness system. The car door wiring harness system is also one of the more complex wiring harness systems in the car, so special attention should be paid when arranging the wiring harness.

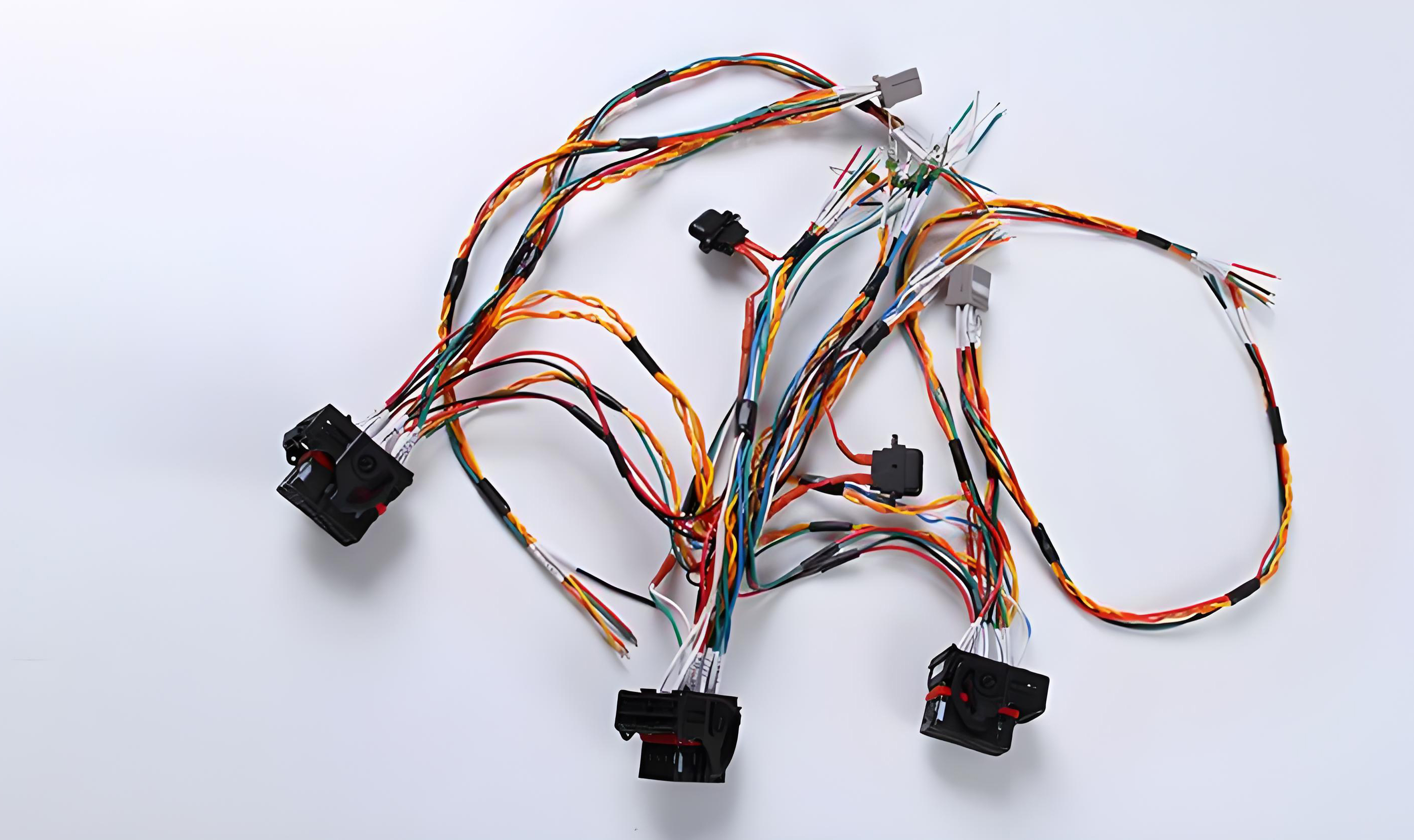

The car door is one of the important functional components of the car, and the electrical configuration and functional requirements of the car door are also increasing. Therefore, the wiring harness connecting various electrical components is becoming more and more complex, becoming a frequent link for modern car failures. Therefore, it has received increasing attention in car design and manufacturing. The car door integrates important electrical components such as switches, buttons, glass lifters, horns, door locks, etc. The door harness must meet the working connection requirements of these parts.

The door wiring harness is distributed on both the dry and wet sides of the door, with multiple branches and fixing points. Effective door wiring harness layout is an important part of ensuring functional implementation, including the branches and connectors of important electrical components.

To ensure the rationality of the design and safety of the car door wiring harness, the layout of the wiring harness should follow the following principles.

- Strong assembly operability. Wiring harnesses are often fixed with clamps or buckles to prevent them from falling off. During assembly, simply press the buckles onto the corresponding holes and use as few buckles as possible to secure as many harnesses as possible, reducing the number of openings on the vehicle body.

- In general, a fixing point needs to be added at a distance of 120mm from the wire harness connector to minimize the burden of wire harness vibration and quality on the terminals inside the connector.

- Within the maximum tolerance required for online assembly, the wiring harness arranged near the moving parts must have sufficient clearance between them, which is determined by the amount of movement of the moving parts. Within the maximum tolerance required for online harness assembly, if the harness is not fixed to the corresponding component, it must have a minimum gap of 6mm from the stationary component.

- When wiring the car door harness, try to keep it away from hot areas and moving parts areas as much as possible.

- For the wiring positions of automotive moving parts and connectors, sufficient wire length should be left according to the vibration amplitude of the automotive parts and the maximum movement stroke of the moving parts to avoid subjecting the wiring harness to tension or tension. When arranging wire harness branches, the selected location should be as open as possible, and the length margin should be as long as possible. In the case of a loose wire harness, it should generally be greater than 25mm to prevent wear or tensile stress damage to the wire harness caused by moving parts during movement.

- In areas with strong electromagnetic interference, attention should be paid to adding anti-magnetic protection to the wiring harness, and special wires such as twisted pair or shielded wires can also be used.

- Wiring harnesses should avoid routing from sharp objects, metal frame edges, welding seams, and fixed holes on the vehicle body, especially at corners. When bypassing sharp angles or passing through holes, rubber or felt pads or protective covers should be used for key protection to prevent functional failure caused by harness wear and tear.

- Each connector must be matched and maintain good contact between the joints.

- The wiring harness should be arranged on the dry side of the car door as much as possible to prevent water leakage from affecting the wiring harness.

At present, there are two installation methods for the door wiring harness. One is to directly fix the wiring harness on the door sheet metal hole; Another method is to integrate it onto the door module and install it onto the sheet metal through the door module. Japanese and Korean car series, as well as domestic brands, mostly use the first fixed method, while European and American models mostly use the second method.

Recent Posts

2025-04-16 11:04:36

What is a wire-to-board connector?

2025-04-16 09:20:46

How to choose House Electrical Wiring?

2025-04-15 09:27:05