Discover the Role of Wiring Harness Technology in Modern Industries | Kaweei

In this era of Industry 4.0, which is evolving at a staggering pace, beneath the surface of every precise mechanical operation lie a multitude of concealed technological enigmas. Today, let's draw back the curtain on the "invisible champion" within the industrial realm – the industrial wiring harness. Discover how these components, which may seem unassuming at first glance but are truly of paramount importance, intricately weave together efficient and stable operational networks across the vast expanse of the industrial landscape.

🔍 [What is an Industrial Wiring Harness?] 🔍

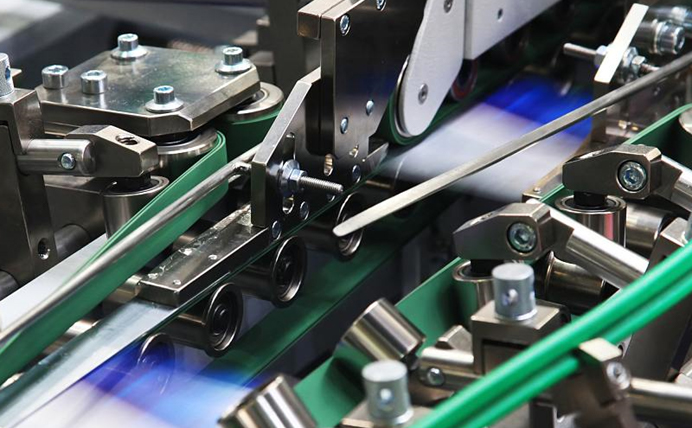

Put simply, an industrial wiring harness is a meticulously crafted, modular, and standardized electrical connection ensemble. It is assembled by bringing together wires, cables, and associated connecting devices such as terminals and connectors, in strict accordance with specific design blueprints and electrical performance benchmarks, via professional technical procedures. Resembling the human nervous system, it shoulders the crucial responsibility of transmitting electricity and signals within complex industrial apparatuses, thereby guaranteeing the seamless operation of the entire system.

🔧 [The Importance of Industrial Wiring Harnesses] 🔧

Efficient Transmission: Industrial wiring harnesses possess the remarkable ability to transmit electrical energy and signals with both efficiency and precision. They constitute the bedrock upon which automated production and intelligent manufacturing firmly stand.

Space Optimization: Through ingenious design, these wiring harnesses can be artfully arranged in a compact manner within the equipment, liberating significant amounts of space and simultaneously enhancing the integration and aesthetic appeal of the machinery.

Safe and Reliable: By employing top-notch materials and adhering to rigorous production methodologies, industrial wiring harnesses exhibit excellent insulation properties, outstanding wear resistance, and formidable corrosion resistance. This effectively thwarts potential safety perils like short circuits and open circuits.

Convenient Maintenance: Thanks to their modular architecture, replacing or repairing wiring harnesses becomes a straightforward and expeditious task. This not only slashes maintenance costs but also amplifies the maintainability of the equipment.

🔬 [Technological Innovation and Development Trends] 🔬

With the relentless march of technology, industrial wiring harnesses are in a state of perpetual evolution. There has been a shift from the utilization of traditional PVC insulating materials to the adoption of environmentally friendly, halogen-free flame-retardant substances. They have also transitioned from serving single functions to integrating multiple capabilities, combining data transmission, power distribution, and signal control. Moreover, they are now trending towards intelligence and networking, gradually carving a path towards greater efficiency, enhanced environmental friendliness, and heightened intelligence.

Looking ahead, as burgeoning fields such as new energy vehicles and smart homes experience explosive growth, even more exacting demands will be placed on the performance, quality, and safety of wiring harnesses. Consequently, wiring harness manufacturing is poised to gravitate towards high precision, superlative efficiency, and ecological sustainability.

🚀 [Wide Range of Application Scenarios] 🚀

From the assembly lines of automobile manufacturing to the cutting-edge technologies of aerospace, from ubiquitous electronic devices to highly automated production lines, the presence of industrial wiring harnesses is ubiquitous. They not only underpin the metamorphosis and elevation of traditional manufacturing sectors but also emerge as indispensable linchpins in novel domains like new energy, the Internet of Things, and intelligent manufacturing.

🌈 [Conclusion] 🌈

In this epoch that relentlessly pursues ultimate efficiency and unwavering reliability, industrial wiring harnesses, with their inimitable value, quietly sustain every pulsation of the industrial cosmos. They are not only the tangible manifestation of technological prowess but also the vivid embodiment of human ingenuity and the innovative spirit. In the future, as technology continues to revolutionize, industrial wiring harnesses will unquestionably play an even more pivotal role in propelling industrial progress and actualizing intelligent manufacturing.

Hopefully, through this refined tweet, you can gain a fresh and profound understanding of industrial wiring harnesses. In the grand odyssey of industrial development, every minuscule detail matters, and the industrial wiring harness is undeniably the invisible yet vital bridge that links aspirations with reality. Thank you for your kind attention. Until next time!

Recent Posts

2025-04-16 11:04:36

What is a wire-to-board connector?

2025-04-16 09:20:46

How to choose House Electrical Wiring?

2025-04-15 09:27:05