Industrial Wire Harness and Network Cables

With the rapid development of 5G technology, data transmission has entered a new era, delivering users high-speed, low-latency, and stable connectivity. In industrial automation, however, network cables remain irreplaceable. Through interconnection, communication, and precise control, industrial wire harnesses and network cables provide cost-effective, robust, and highly stable transmission, playing a critical role in smart factories. They are widely applied in automated equipment, robotics, sensor networks, monitoring systems, and industrial control platforms.

Key Considerations in Selecting Industrial Network Cables

Unlike commercial environments, industrial control systems require network cables with extreme reliability and consistency. Even a short-term disconnection, poor contact, or interference may trigger equipment shutdown, alarms, and production loss. Therefore, cable selection must consider:

- Data transmission rate & bandwidth requirements

- Environmental interference resistance (EMI, RFI, crosstalk)

- Mechanical stress (bending, vibration, drag chains)

- Temperature & humidity conditions (corrosion, moisture ingress)

- Connector integrity and installation space

- Overall cost-effectiveness & lifecycle stability

Common Categories of Industrial Network Cables

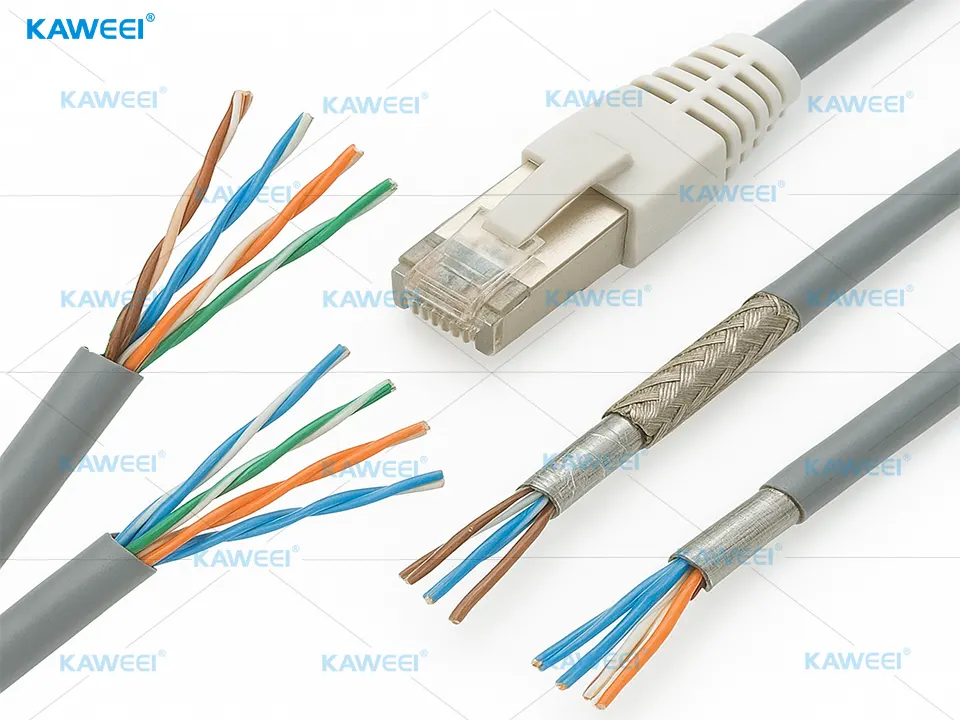

To meet diverse performance requirements, twisted-pair network cables in the industrial field are classified into different categories (Cat5e, Cat6, Cat6a, Cat7, Cat8). Each category is optimized for signal integrity, transmission speed, distance, and bandwidth.

Cable Shielding Structures and Characteristics

- U-FTP (Unshielded Foil Twisted Pair): Each pair individually foil-shielded, plus outer braid shielding; strong confidentiality, high-speed, future-proof for unified wiring.

- S-FTP (Shielded Foil Twisted Pair): Double shielding with foil and braided mesh; excellent anti-interference and secure transmission, suitable for harsh EMI environments.

- U-UTP (Unshielded Twisted Pair): Most widely used; cost-effective, easy to install, supports up to Cat6 standard, ideal for standard industrial Ethernet.

- F-UTP (Foil Twisted Pair): Added foil shielding with moderate interference resistance; often LSZH (Low Smoke Zero Halogen) for safety-critical environments.

- SF-UTP: Entire bundle shielded with foil and braid; strong EMI resistance, used in electrically noisy environments.

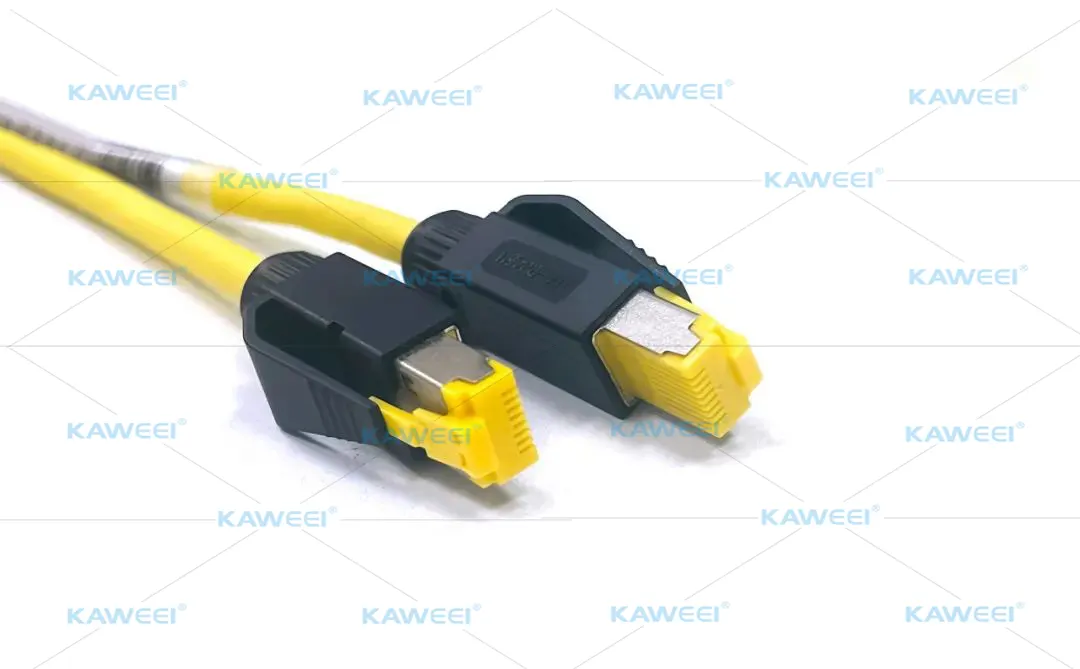

Connector Configurations

Industrial-grade RJ45 connectors are available in multiple variants—long-body, short-body, shielded, unshielded, with plating thickness ranging from 3U to 50U—ensuring reliable mating cycles and adaptability to different installation spaces. For demanding environments, anti-vibration connectors and injection-molded sheaths enhance durability under humidity, chemical exposure, and continuous motion.

Haituo Electronics: Expertise in Industrial Wire Harness Solutions

As a global supplier delivering over 1 million sets of wire harness assemblies annually, Haituo Electronics supports leading automation brands worldwide. With deep manufacturing expertise and rigorous quality assurance, Haituo provides standardized and customized network cable harnesses tailored to customer requirements.

Our Advantages

- Diversified Wire Materials: PVC, PUR, LSZH insulation for varied environments (abrasion resistance, oil resistance, flame retardancy).

- Comprehensive Connector Options: RJ45 long/short body, shielded/unshielded, multiple plating thicknesses.

- Customized Sheath Solutions: Tailor-made molds to match customer installation constraints.

- Rigorous Testing & Validation: Fluke certification, simulated working condition testing, bandwidth verification, ensuring long-term stability and compliance.

With industrial automation evolving rapidly, Haituo continues to innovate in materials, design, and reliability. Guided by quality, delivery efficiency, and cost-effectiveness, we aim to provide high-performance wire harness and network cable solutions that enhance customer competitiveness in smart manufacturing.