Difference between cable assembly and wire harness

Cable Assemblies and Wire Harnesses are two common components in electronic and electrical engineering that have similar functions (transmission of electrical signals or power) but differ significantly in design, construction and application scenarios.

The design and construction of Cable Assemblies and Wire Harnesses are different.

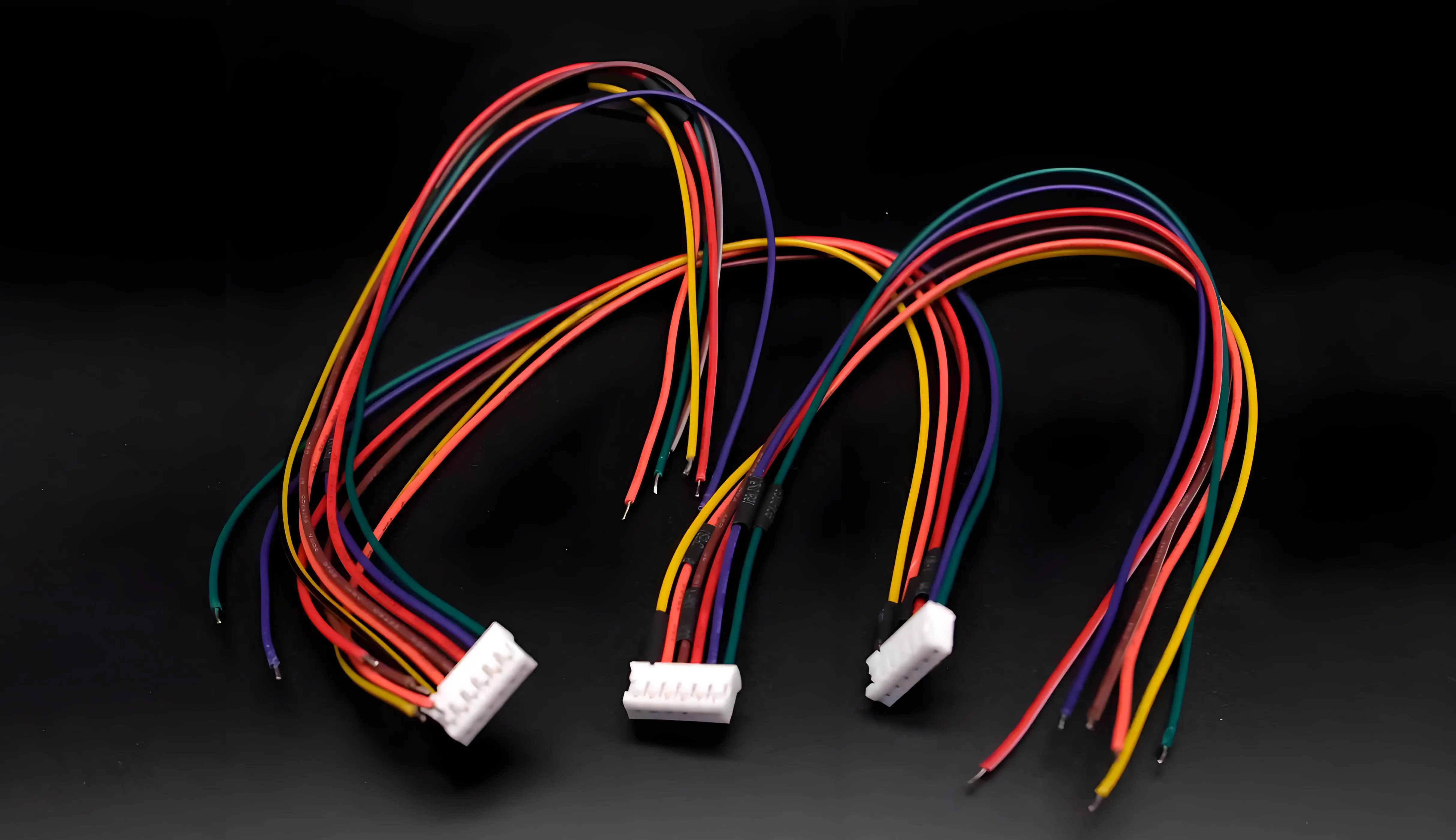

Cable Assembly : This usually refers to the integration of one or more cables with connectors, terminals or other accessories in a sheath (outer protective jacket).

Highly protective materials (e.g. rubber, PVC, metal braid, etc.) are often used.

The result is a complete, pluggable assembly. Cable assemblies are typically used to transmit power, data or signals between or within equipment.

The focus is on protection and durability for harsh environments (e.g. waterproof, oilproof, EMI resistant).

Wire Harness : It is the loose tying together of multiple wires, cables and possibly connectors, terminals, etc., without an overall outer jacket.

It is usually wrapped only in simple insulating material (such as heat shrink tubing or bellows) to make a specific electrical connection.

The structure is lighter and more flexible, mainly used for internal equipment or cabinets with better environmental conditions in the scene.

Wire Harnesses are typically used to organise and manage wires in vehicles, mechanical equipment or other complex systems.

Differences in application scenarios for cable assemblies and wire harnesses:

Cable Assembly:

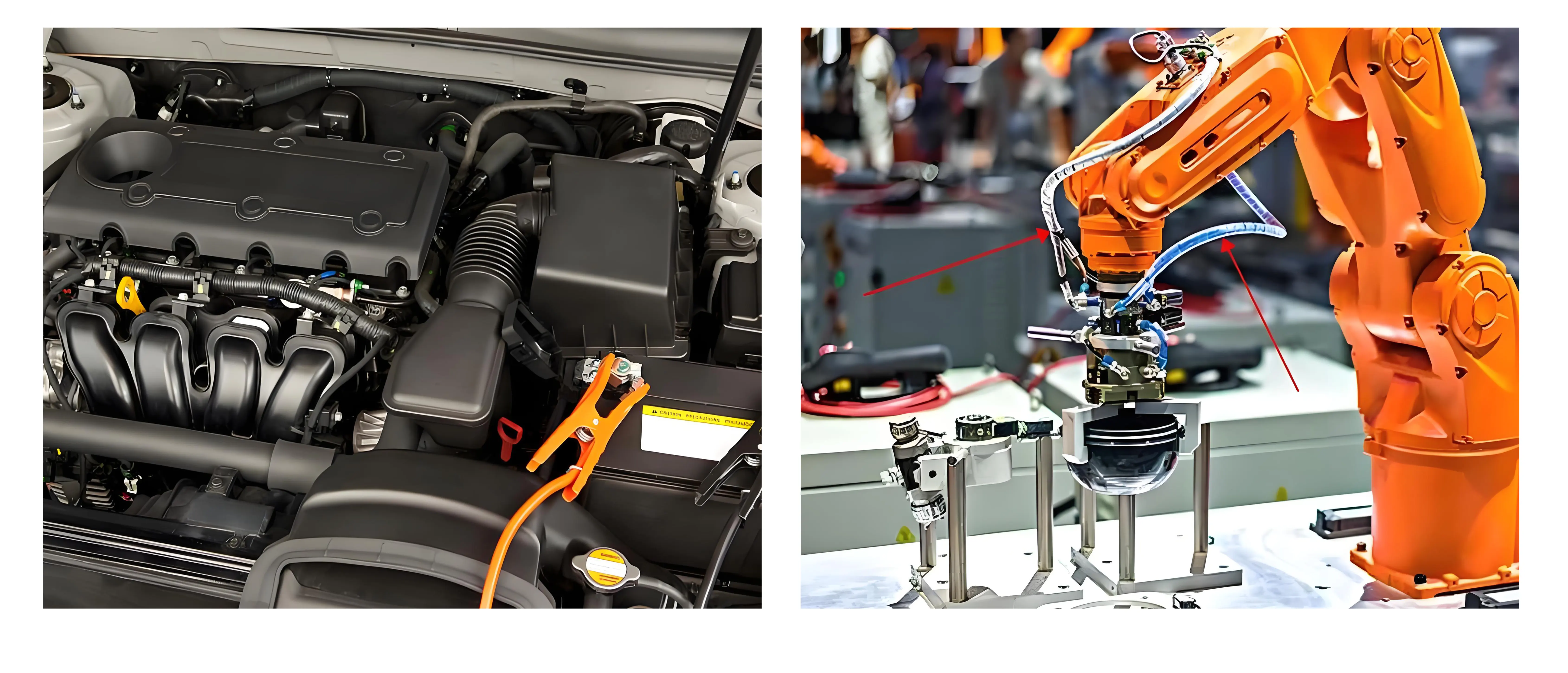

External or complex environments: industrial machinery, automotive external wiring (e.g. sensor cables), medical equipment, aerospace, outdoor equipment.

Scenarios requiring protection: waterproofing, tensile strength, high temperature resistance, chemical resistance or electromagnetic shielding.

Typical examples: automotive engine compartment cables, industrial robot power cables.

Typically used to provide specific electrical connections between or within equipment, such as power, data or signal cables.

Wire Harness.

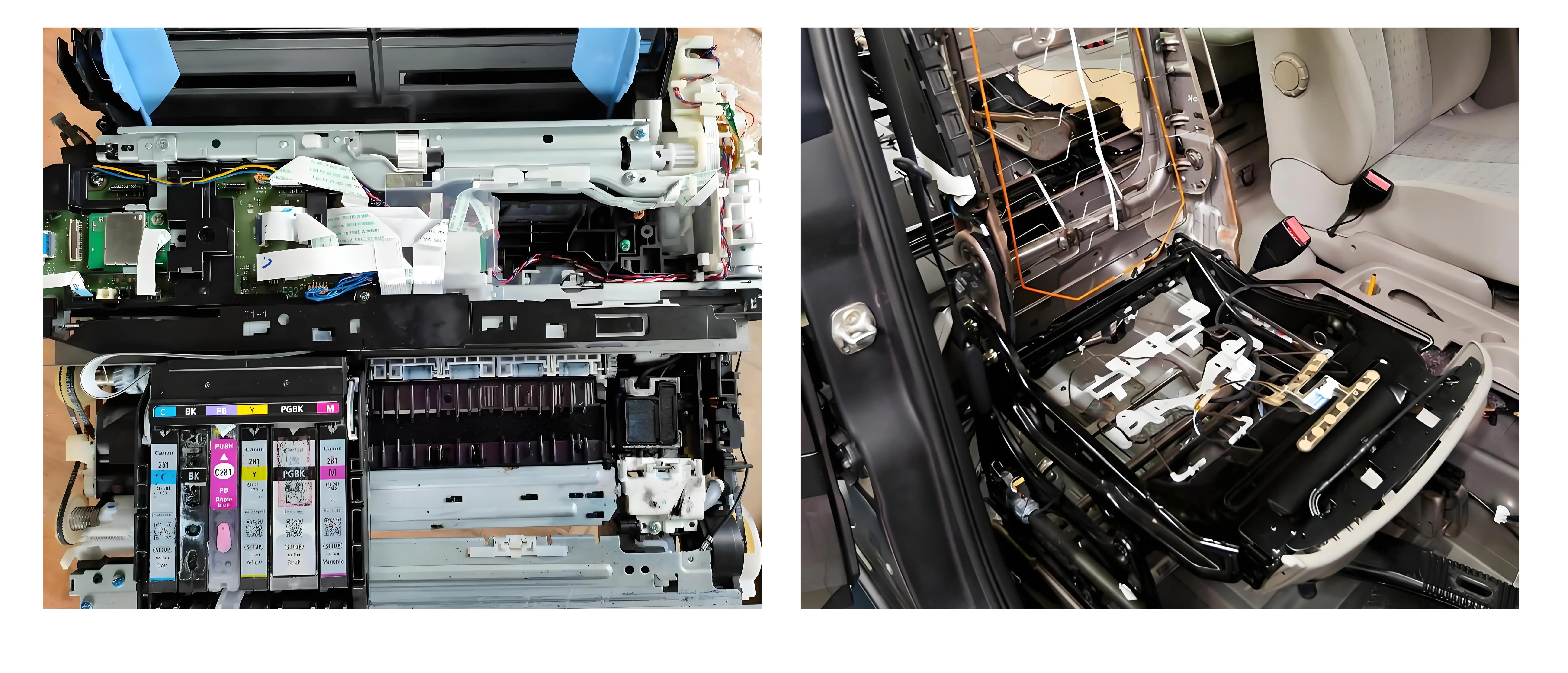

Internal device wiring: automotive dashboards, appliance interiors, computer cases, control cabinets.

Low Cost, Lightweight Scenarios: Low protection requirements, but need to simplify installation and maintenance.

Typical examples: internal wiring harnesses for home printers, car seat heating wiring.

More commonly used in complex systems that need to organise and manage a large number of wires, such as automobiles, aircraft, machinery and equipment. Wire Harnesses help reduce wire clutter and improve system reliability and maintainability.

Customised differences between cable assemblies and wire harnesses:

Cable Assembly.

- Usually highly customised (designed according to length, jacket material, connector type) and more costly.

- Longer production cycles and specialised equipment (e.g. injection moulding machines, shield processing equipment).

- Low maintenance due to high protection, but complicated to replace (complete disassembly required).

- Suitable for fixed installation, low flexibility.

- Can be customised for specific needs, but usually less complex than wire harnesses.

Wire Harness.

- Mostly standardised designs, suitable for mass production, lower cost.

- Simpler to assemble (can be done manually or with semi-automatic equipment).

- Loosely constructed and easy to locally repair or replace individual wires.

- Highly flexible, allowing alignment to be adjusted according to equipment layout.

- Often requires a high degree of customisation to suit the needs of a particular system or piece of equipment.

kaweei is a professional manufacturer of custom wiring harnesses and cable assemblies, if you need to know about wiring harnesses or cable assemblies, you can contact us at any time.

Recent Posts

2025-05-23 10:08:35

How to choose industrial wiring harness

2025-05-22 09:47:36

Custom Audio Cable Manufacturer

2025-05-17 09:54:29