Design of automotive wiring harnesses

What is an automotive wiring harness?

Automotive wiring harness is the nervous system of the car, used for power and signal transmission and distribution. It generally consists of open wires, connecting plastic parts, metal terminals, tapes and other positioning parts, protection parts and so on.

What is the classification of automotive wiring harness: instrument panel wiring harness, engine wiring harness, body wiring harness, door wiring harness, roof wiring harness, battery power harness, licence plate light wiring harness, and so on.

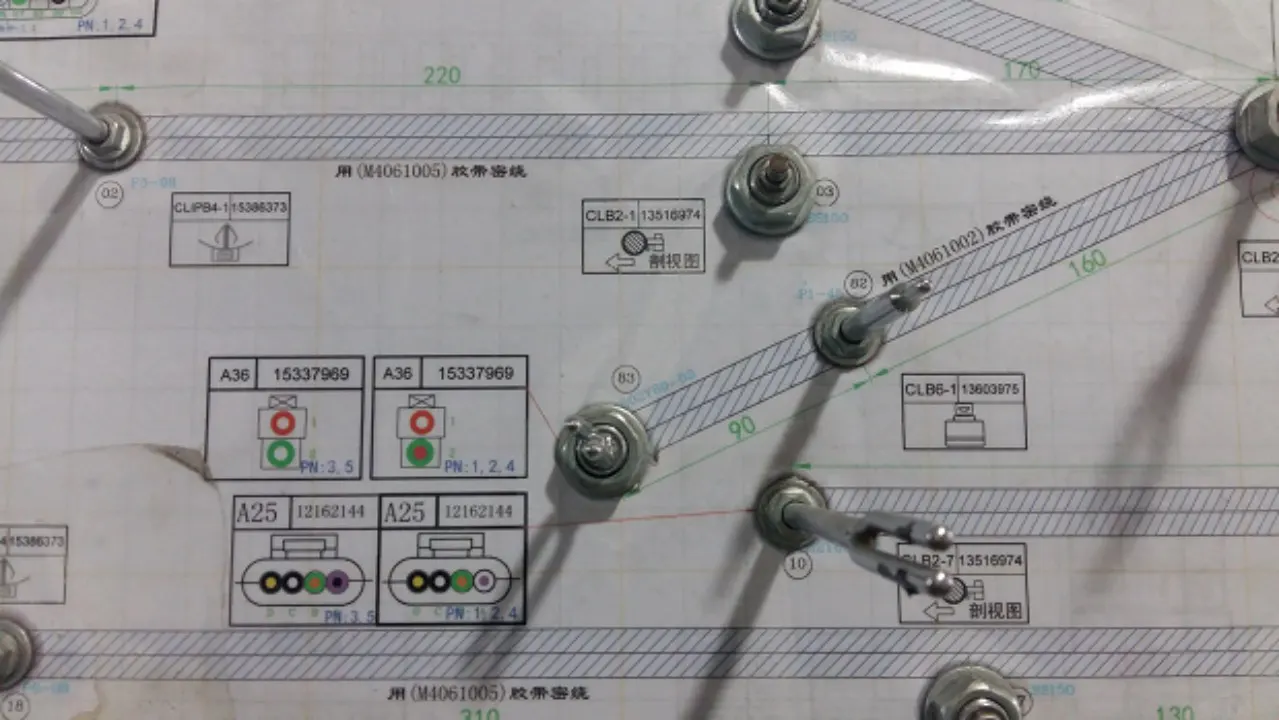

The production process of automotive wiring harness: raw materials, cutting line, subassembly, assembly, total assembly.

Classification of raw materials:

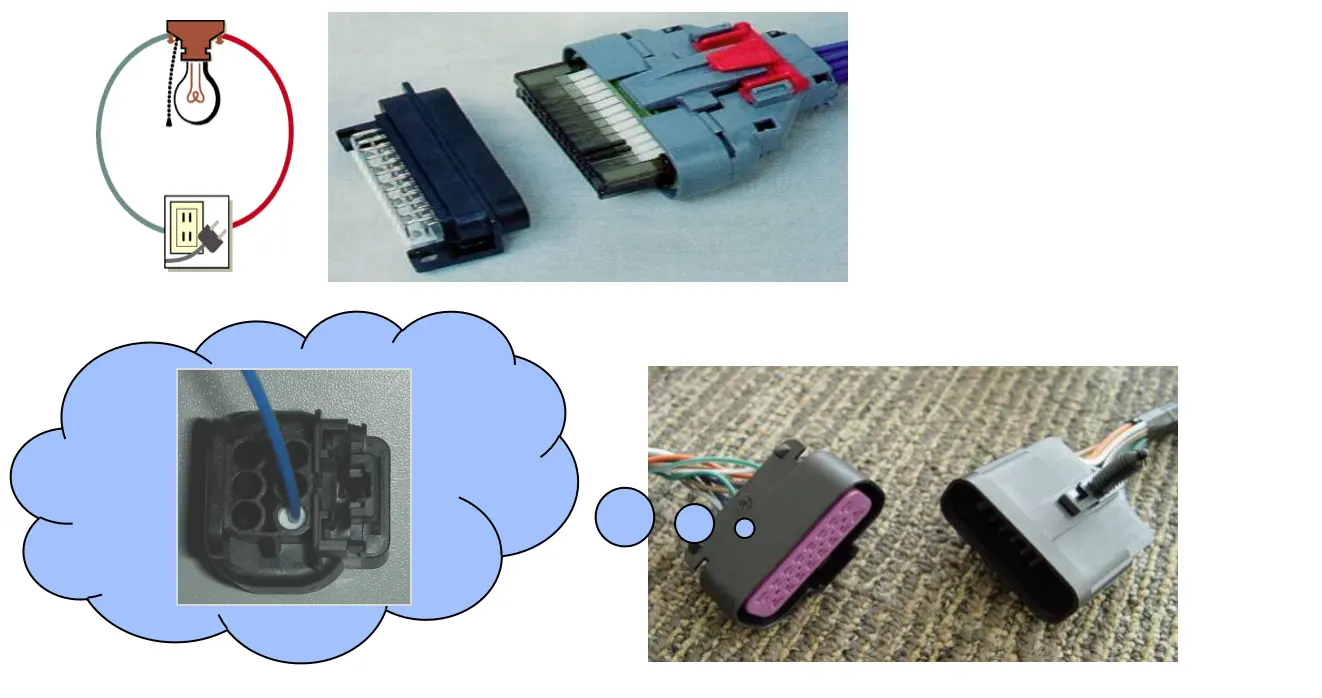

1. Electrical connection materials: wire (wire), connector (secondary lock), terminals.

Wire: copper-core wire covered with different colours of insulation, used to transmit signals and power from one end to the other.

Connector: A connecting part, usually made of plastic, into which a wire with a terminal is usually inserted to provide a connection between the wire and the wire, and between the wire and the appliance.

Terminal: A shaped hardware part (usually made of copper) that is crimped onto a wire to connect and transmit signals.

2. Covering/protective materials: tape, pipe (bellows/PVC pipe), seals, rubber sheathing

Tape: Wrapped around the surface of the wire harness, used to avoid wire exposure, play a role in protecting the wire.

Tube: A part made of PVC material to protect wires from water, heat, abrasion and dust.

Seal: made of rubber/plastic, worn on the wire or inserted in the plug, waterproof sealing function. (Mainly used in automotive wiring harnesses in wet areas)

Rubber sheath: made of rubber, worn on the wires, it is the transition part connecting the dry zone and the wet zone, and serves as a waterproof sealing, vibration damping, anti-abrasion, and dust-proof function.

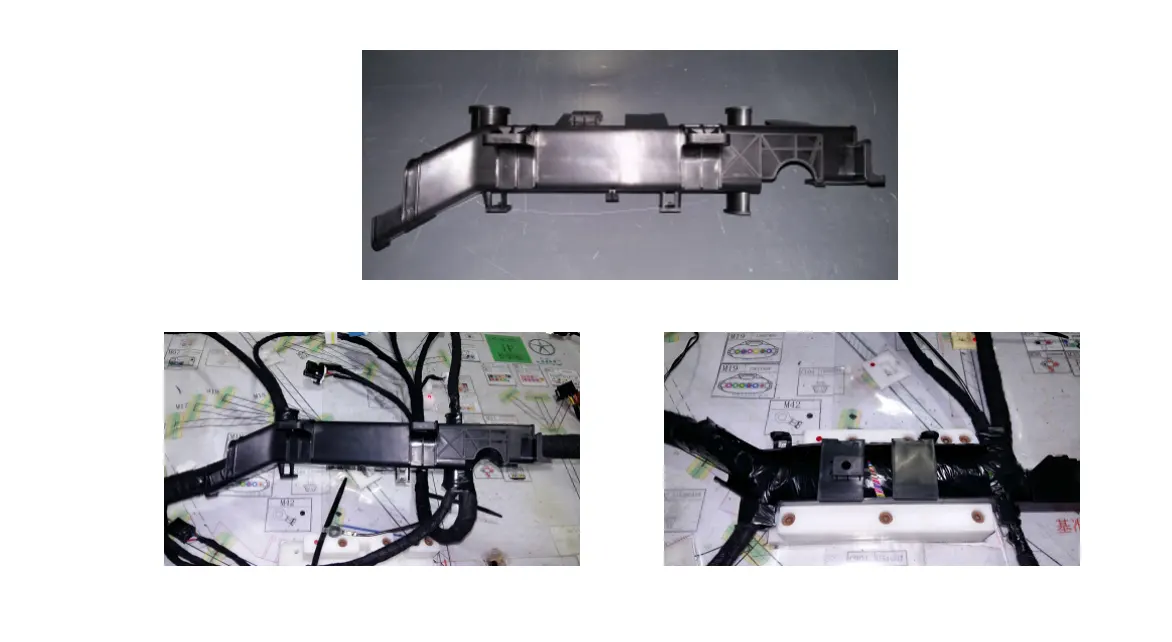

3. Fixed materials: bracket (trunking), positioning parts (nails/ties)

Bracket (slot): made of plastic, fixed in the harness outside, play a role in shaping and protection.

Positioning parts: usually made of plastic, fixed outside the wiring harness, is the wiring harness in the car fixed on the important components.

Automotive wiring harness assembly is divided into two processes: sub-assembly and assembly

Sub-assembly process: Mainly assembly of electrical components.

1. plugging

2. Installation of secondary locks/blind plugs/blind pins

Assembly process: mainly assembly of coverings and fixtures

1. Assembly of coverings: Assembly of coverings: winding of tapes, installation of tubes (bellows/PVC/fibre tubes), installation of sheathing

2. Installation of fixings/brackets

Come to kaweei for your customised automotive wiring harness, we are waiting for you.