Cable Harness for Energy Storage Battery

I. Design Principles

Electrical Performance Optimization

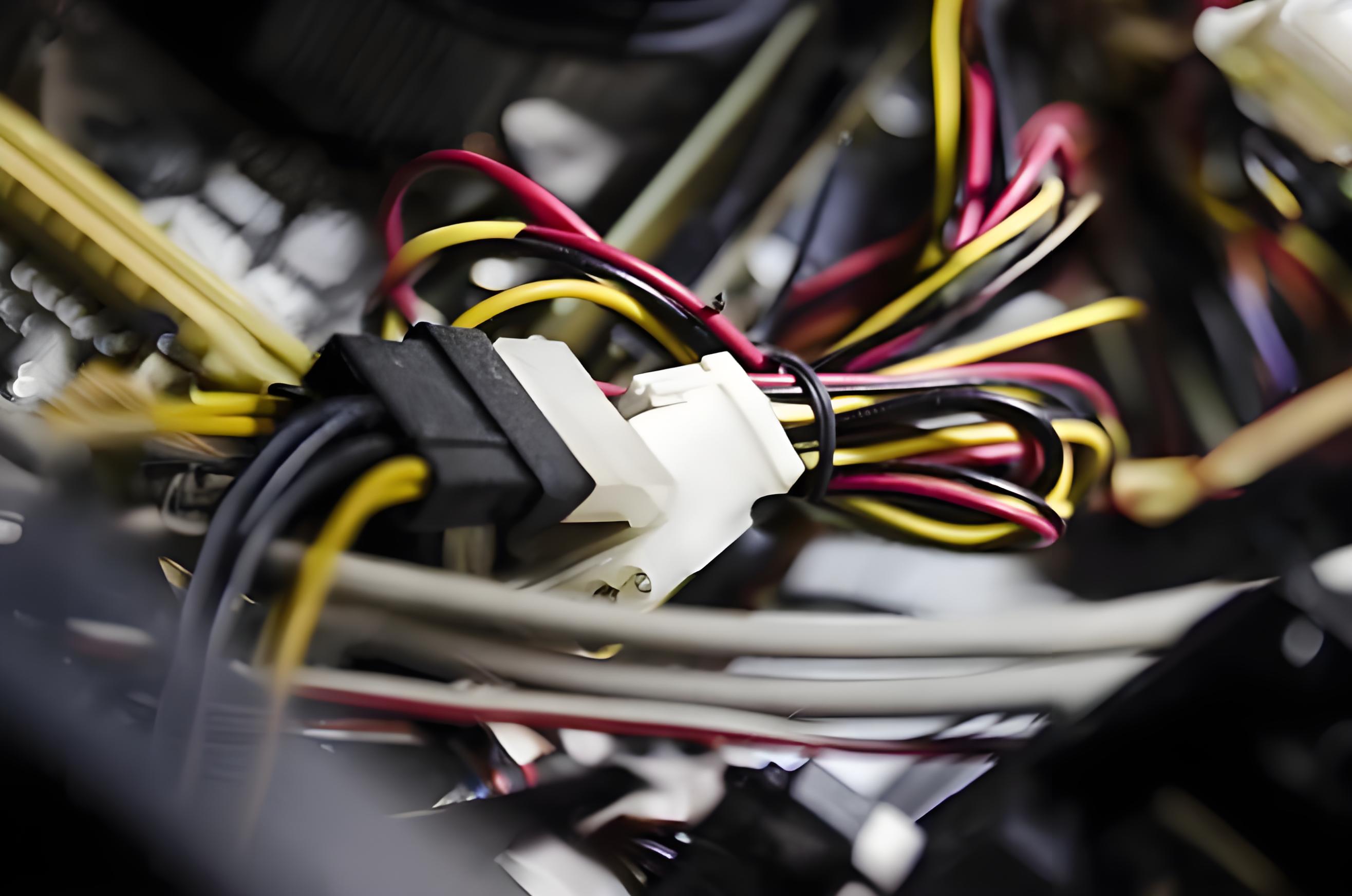

For power transmission, the cable harness is designed with conductors of appropriate cross-sectional area. High - High-conductivity materials like copper are selected to minimize power loss during energy transfer. For example, in large-scale energy storage systems with high-power requirements, thick-gauge copper wires are used to ensure that the voltage drop is within an acceptable range, maintaining the stable operation of the battery clusters.

In terms of communication, shielded cables are often employed. The shielding layer can effectively prevent electromagnetic interference from external sources, such as nearby power lines or industrial equipment. This ensures the accurate and stable transmission of communication signals between battery modules, enabling real-time monitoring and control of the battery state.

Mechanical Durability

The cable harness is designed to withstand various mechanical stresses. In an energy storage system, the battery clusters may be subject to vibrations, temperature changes, and even physical impacts during installation and operation. Therefore, the outer sheath of the cable harness is made of durable materials, such as high-strength thermoplastics or rubber compounds. These materials can resist abrasion, and corrosion, and maintain their shape under different environmental conditions.

II. Advantages of the Designed Cable Harness

Enhanced System Reliability

By ensuring a stable power supply and reliable communication, the designed cable harness significantly improves the overall reliability of the energy storage battery clusters. For instance, in a grid-connected energy storage system, any interruption in power or communication can lead to inefficiencies in power regulation and potential damage to the battery modules. The well-designed cable harness minimizes such risks, enhancing the stability of the entire energy storage system.

Scalability

The modular design of the cable harness allows for easy expansion of the energy storage battery clusters. As the energy storage needs grow, additional battery modules can be seamlessly integrated into the existing system. The standardized connectors and cable lengths in the design facilitate this process, reducing installation time and costs.

III. Application Scenarios

Grid - Connected Energy Storage

In large-scale grid-connected energy storage projects, the communication and power cable harness plays a vital role. It enables the connection between numerous battery modules in the battery clusters and the grid-side power conversion equipment. Through accurate communication, the battery clusters can respond in real time to the grid's power demand, providing peak-shaving, and frequency-regulation services.

Off - Grid Renewable Energy Systems

For off-grid renewable energy systems, such as solar-powered remote stations or wind-energy-based isolated communities, the cable harness is essential for powering and coordinating the battery clusters. It ensures that the energy harvested from renewable sources is efficiently stored and distributed to meet the local power needs.

In conclusion, the design of the communication and power cable harness for energy storage battery clusters is a complex yet crucial aspect of energy storage technology. With continuous innovation in design principles and materials, it will continue to drive the development of more efficient and reliable energy storage systems.