Automotive High Voltage Wiring Harness Guide

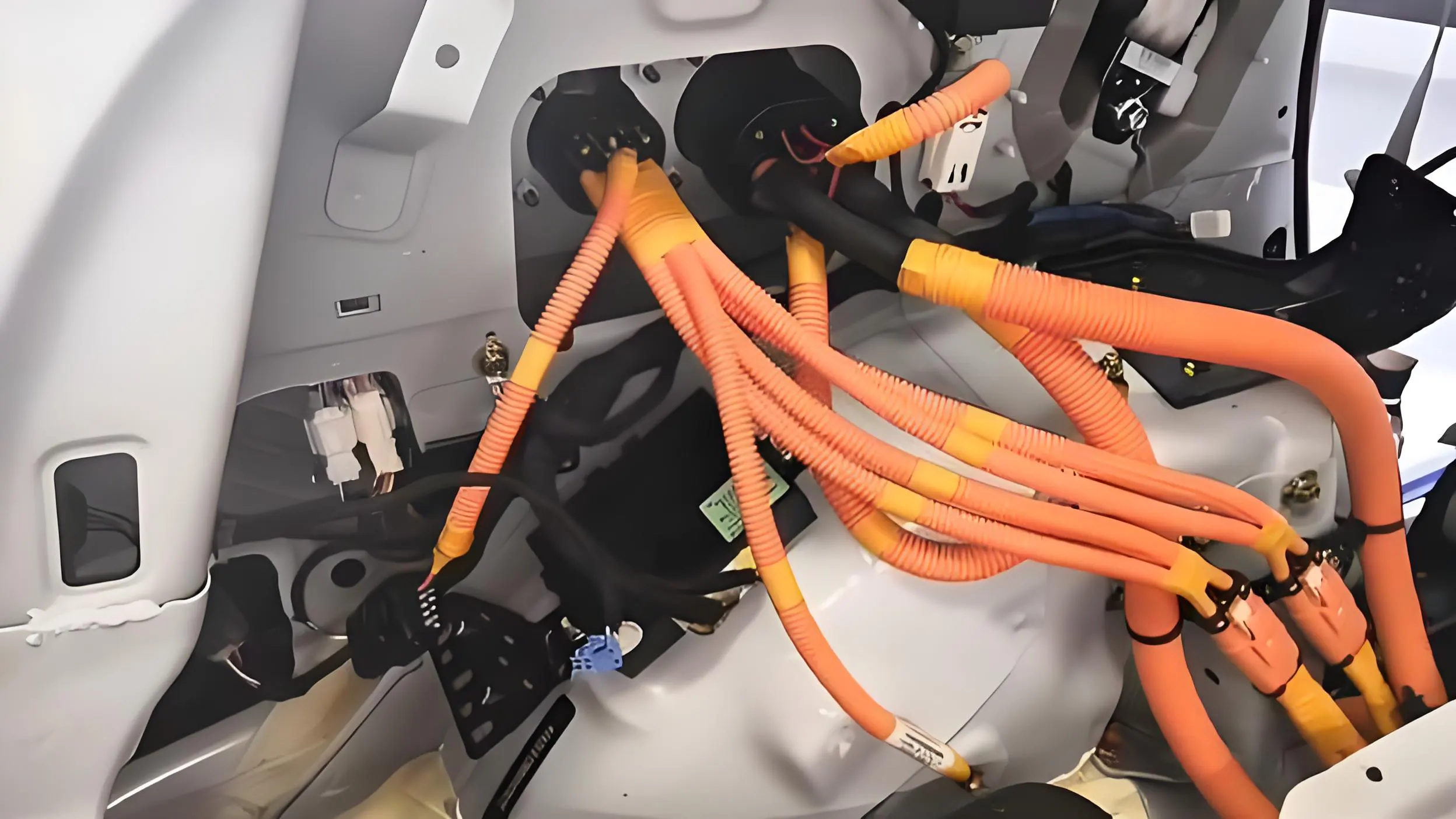

Automotive high-voltage wiring harness is a kind of cable system that has gradually become a key element with the popularity of automotive technology, especially electric and hybrid vehicles.

I. Definition and Role

High-voltage wiring harnesses are cable systems used to transmit high-voltage electrical signals, which are mainly used in electric and hybrid vehicles.

These harnesses usually connect batteries, inverters and motors to ensure the efficient transmission of electrical energy.

II. Composition High-voltage wiring harnesses are usually composed of the following parts:

The conductor is usually made of copper or aluminium and has good electrical conductivity.

Insulation is essential to prevent current leakage and short circuits.

Insulation materials are usually cross-linked polyethylene (XLPE) or fluoroplastics, which are resistant to heat and abrasion and have excellent electrical insulation properties.

The outer layer of protection for high-voltage harnesses is usually made of materials that are resistant to heat, oil, and chemicals.

Connectors are used to connect the wire harness to equipment such as batteries and inverters. High-voltage connectors need to have good waterproof, dustproof and shockproof ability to adapt to the complex automotive working environment.

III, the characteristics and requirements of the safety of high-voltage wiring harness design and manufacturing is directly related to the safety of the car.

As the high-voltage wiring harness carries the electric energy of the electric vehicle, once the failure occurs, it may lead to short circuit, fire and other serious consequences. Therefore, strict production standards and testing procedures are important to ensure the safety of high-voltage wiring harnesses.

Performance The performance of the high-voltage wiring harness affects the overall performance of the vehicle. For example, the resistance and conductivity of the wiring harness directly affects the efficiency of current transmission, which in turn affects the power output and range of the motor.

High-quality high-voltage wiring harnesses can effectively reduce energy loss and improve the overall performance of electric vehicles.

Durability High-voltage wiring harnesses need to withstand a variety of complex environmental conditions, such as high temperature, low temperature, humidity, vibration, etc., during the life cycle of the vehicle. Therefore, the material selection and manufacturing process of the harness must have good durability.

Durable high-voltage wiring harnesses can reduce the frequency of maintenance, reduce the cost of use, and improve consumer satisfaction.

IV, classification and layout. In new energy vehicles (pure electric for example), the high voltage wiring harness can be divided into the following five major parts:

- Power battery high-voltage cable

- Connecting the power battery to the high-voltage box between the wiring harness

- Motor controller cable connecting the high-voltage box to the motor controller between the harnesses

- Fast charging harness connecting the fast charging port to the harness between the high-voltage box

- The slow charging harness connects the harness between the slow charging port and the on-board charger.

V. High-voltage accessory harness (high-voltage harness assembly):

connecting the high-voltage box to the DC/DC, on-board charger, air-conditioning compressor, air-conditioning PTC between the harness electric vehicle high-voltage wiring harness arrangement should follow the principle of proximity to minimise the use of high-voltage cables, and at the same time to meet the general layout and high-voltage electrical design requirements.

In addition, attention should also be paid to avoid electromagnetic interference, leakage, fire and other safety hazards.

VI, note that the arrangement of high-voltage wiring harnesses need to follow a series of safety requirements, such as.

- Visual concealment, compliance with safety crash regulations, consideration of ergonomics and ease of maintenance, etc.

- In the arrangement of high-voltage wiring harness, must ensure that the driver or maintenance personnel can not directly access the high-voltage wiring harness

- When arranging high-voltage wiring harnesses, special attention should also be paid to avoiding areas with excessive extrusion and vibration. In short, automotive high-voltage wiring harnesses are an important part of electric and hybrid vehicles, and their safety, performance and durability are directly related to the overall performance and service life of the vehicle. Therefore, it is necessary to strictly comply with the relevant standards and processes during the design and manufacturing process to ensure the quality and reliability of high-voltage wiring harnesses.

Recent Posts

2025-04-02 10:50:47

What is UL Standard?

2025-04-02 08:57:29

Difference between electronic wire and cable

2025-04-01 11:17:45