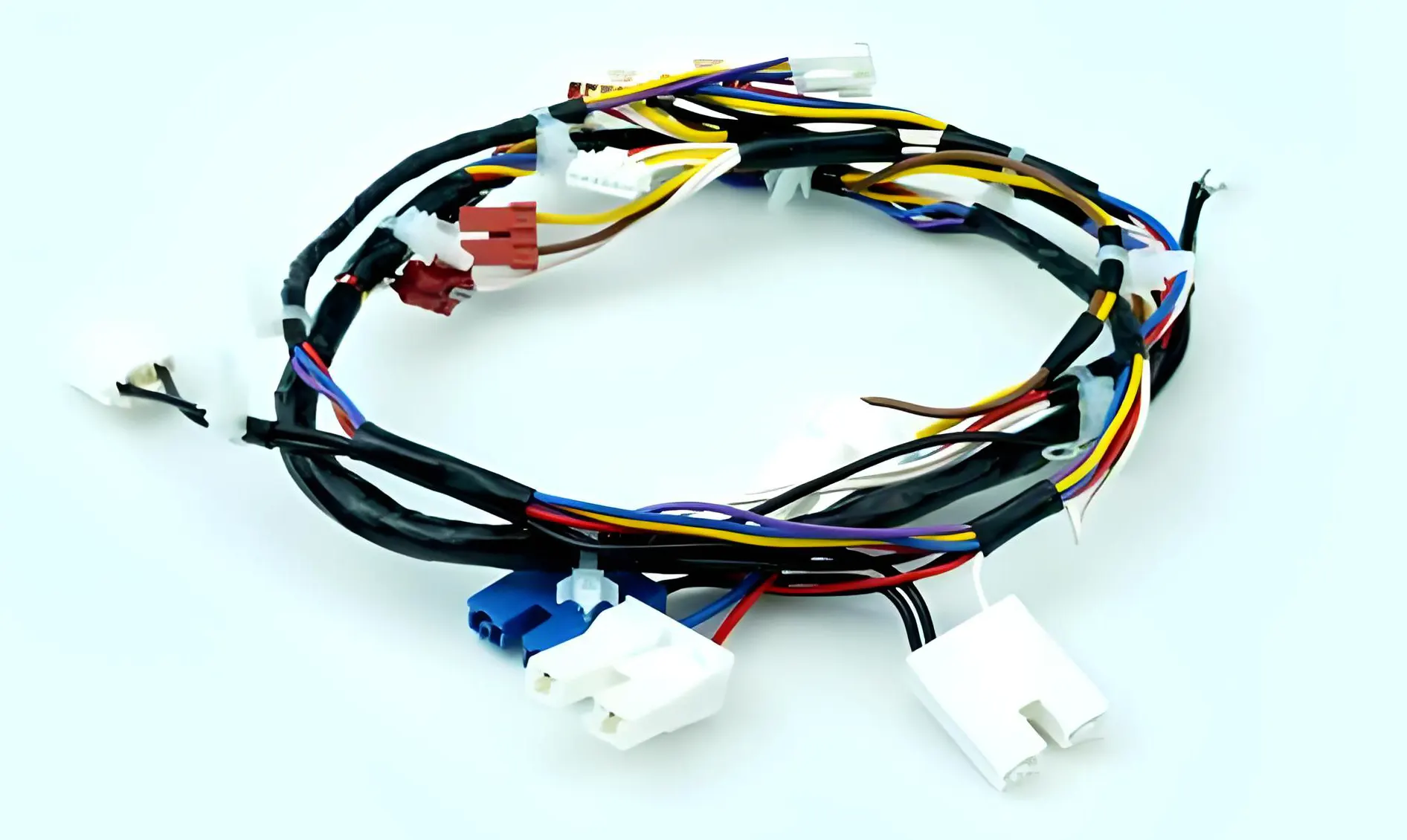

wiring harness in sweeping robot

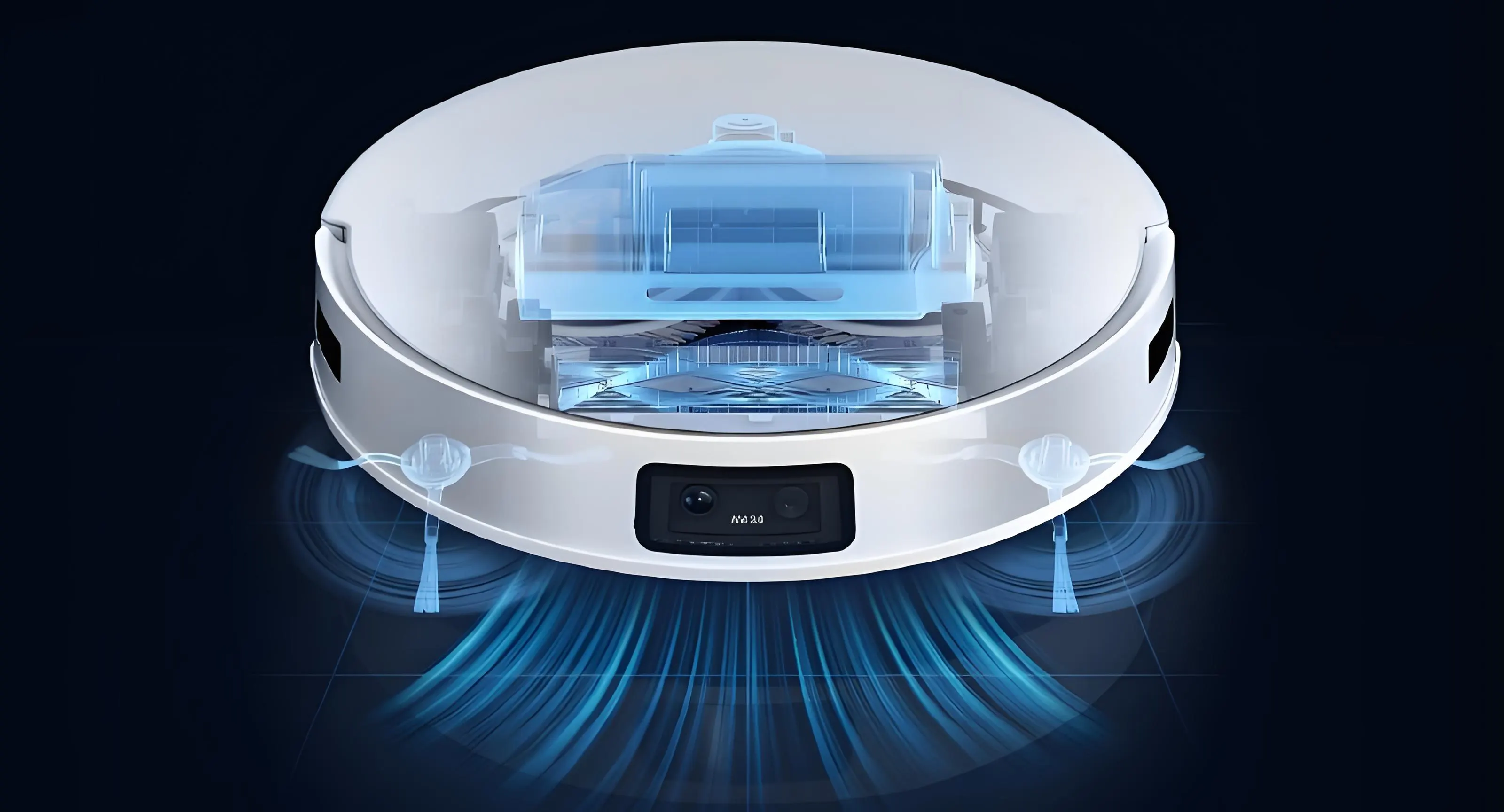

In the modern smart home, sweeping robots are widely welcomed for their efficient and convenient cleaning ability.

And behind this, the application of wiring harness plays an irreplaceable role.

- The wiring harness connects the battery pack, motor and charging module to provide stable power support for the sweeping robot.For example, the power harness needs to be adapted to the high energy density characteristics of lithium batteries to ensure low-loss transmission, while the intelligent management module to achieve overcharge protection

- Sweeping robots rely on LIDAR, collision sensors, gyroscopes and other types of sensors to realize the environment perception.The sensor harness transmits the collected data to the main control chip in real time, and adjusts the motion path by driving the motor through the control harness. For example, Corvus T80 realizes dynamic obstacle avoidance and edge-to-edge cleaning through the high-precision sensor harness

- Models supporting Wi-Fi or Bluetooth need a special communication harness to connect to the wireless module to realize remote interaction with the user terminal.This kind of harness needs to take into account the signal shielding and anti-interference ability, to avoid electromagnetic interference affecting the navigation accuracy

The wiring harness is arranged in a scientific and reasonable manner, not only to ensure the transmission efficiency, but also to avoid mutual interference.

Usually, the wiring harness will be laid out along the internal structure of the robot to minimize bending and crossing, in order to reduce signal attenuation and power loss.

In terms of performance, sweeping robot wiring harnesses excel.

They are made of high-quality materials with excellent conductivity, insulation, and abrasion resistance.

This allows the harness to maintain stable performance over long periods of time and high frequency use, effectively avoiding robot downtime due to harness failure.

At the same time, the wiring harness also has good flexibility, can adapt to a variety of complex robot movement and attitude changes, to ensure its stable operation in different environments.

Harness technology directly affects the reliability of the sweeping robot, cleaning efficiency and intelligence level.

With the robot to the “body intelligence” evolution (such as the pursuit of bionic robot model), the harness will further integrate more functional modules, and through the lightweight, intelligent design to promote the development of family service robots to higher-order form.

In the future, wiring harnesses will not only be the bridge connecting the hardware, but will also be the key carrier to enhance the autonomous decision-making ability of robots.