Plastic Injection

Kaweei provides professional plastic injection molding services for wire harnesses.

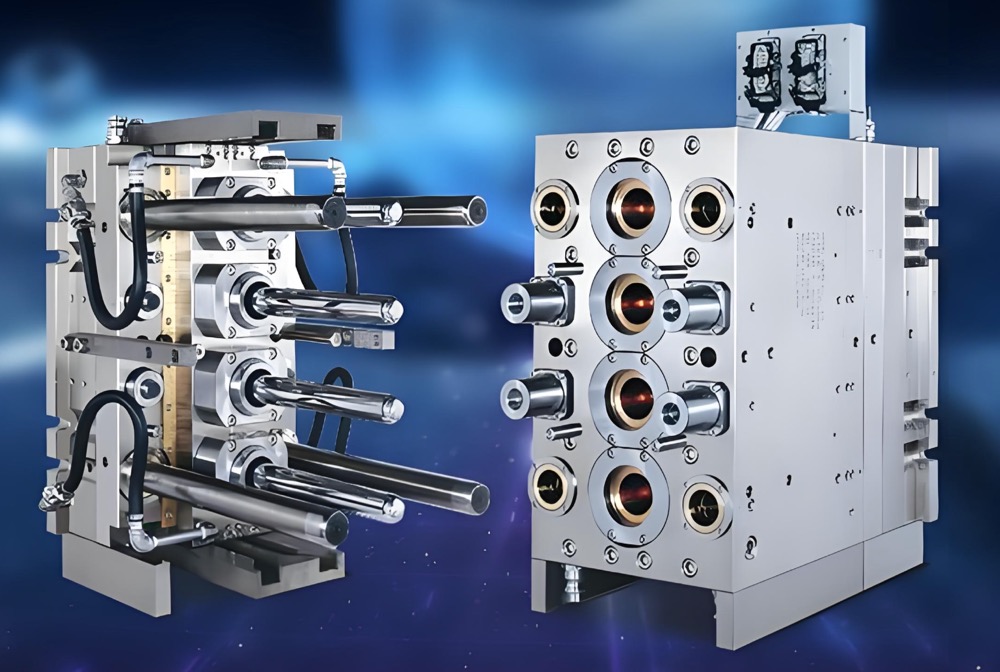

In the wire harness industry, plastic injection molding plays a key role in producing durable, high-quality components such as connectors, cable grommets, and protective housings. Kaweei is a leading expert in the field of plastic injection molding, providing comprehensive solutions tailored to the specific needs of the wiring harness industry. With 10 advanced injection molding machines and over 300 mold libraries, we provide precision engineering plastic components that meet the highest industry standards.

Our plastic injection molding capability

1. Advanced mechanical equipment

10 high-precision injection molding machines:

Our injection molding machines range from low tonnage machines for small and complex components to high tonnage machines for larger and more complex parts. These machines can achieve fast and accurate production, ensuring consistent product quality.

2. Rich mold library

300+precision molds:

We have reserved a large number of molds for various wire harness components, including:

Connector housing

Wire loops and seals

Cable clamps and stress eliminators

Customized designed protective cover

Our internal mold maintenance and customization services can quickly adjust tools and reduce production downtime.

Why choose Kaweei?

Comprehensive capability: From design to final production, we provide a one-stop solution for plastic components of wire harnesses.

Expert engineering team: Our experienced professionals ensure precise mold design and efficient production.

Quality assurance: Each component undergoes rigorous testing to meet industry standards such as ISO and IPC.

Economically efficient solution: High production efficiency can reduce costs while maintaining high-quality products.

Customization and Innovation: We constantly upgrade our processes and mold designs to adapt to industry trends.

At Kaweei, we are committed to providing high-performance plastic components for the wiring harness industry through advanced plastic injection molding. Our state-of-the-art facilities, extensive mold inventory, and experienced team ensure that we can accurately and reliably meet the most complex manufacturing requirements.