Automation

Key Features of Kaweei Automated Wire Processing

Core Automation Functions

1. Wire Cutting

Precision Cutting:

Automated cutting machines ensure precise wire lengths, minimizing material waste and ensuring consistency across production batches.

2. Wire Stripping

Single and Multi-layer Wire Stripping:

Our machines precisely remove insulation, leaving wire ends clean and undamaged for optimal conductivity.

3. Terminal Crimping

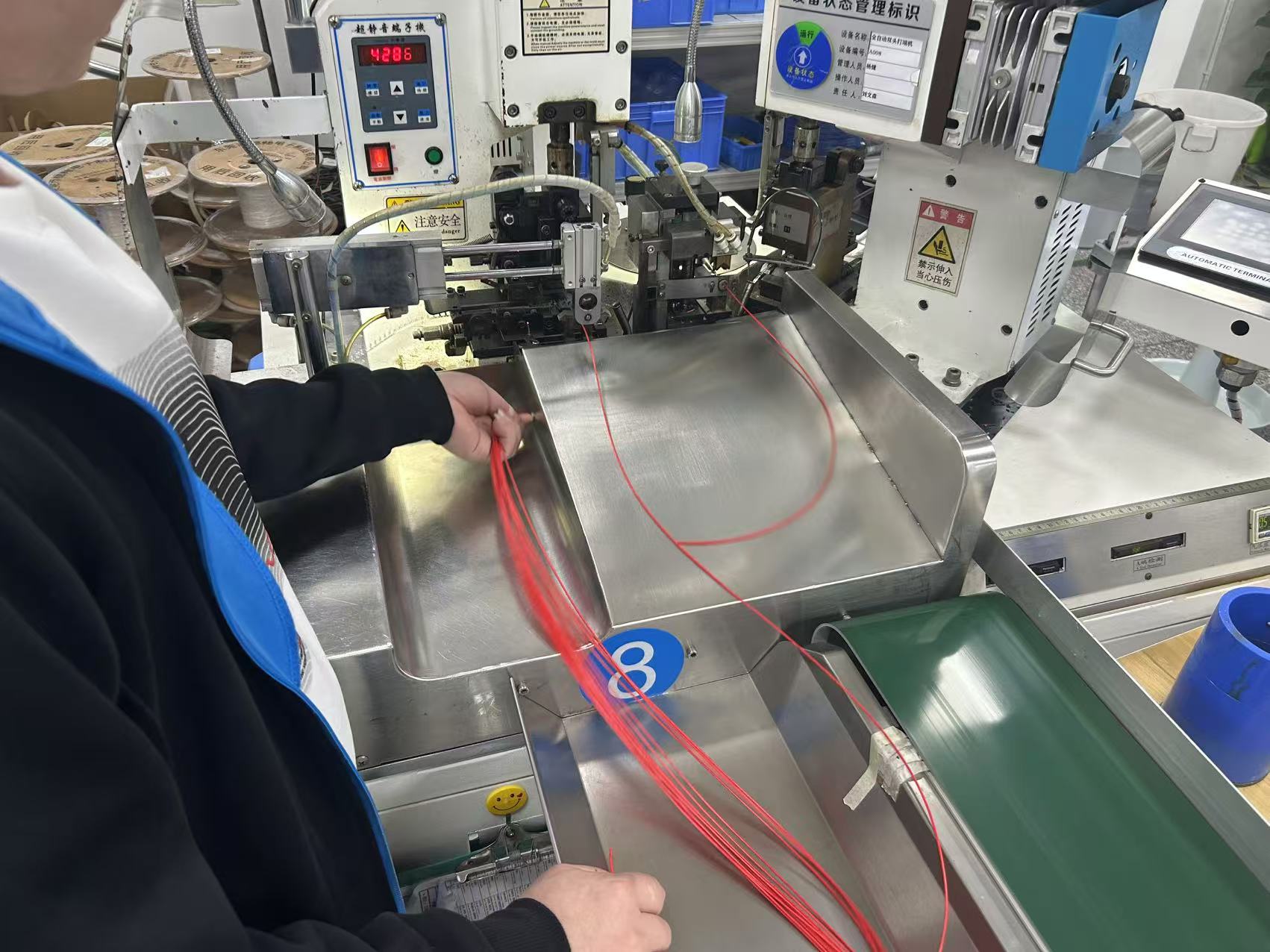

High-quality Crimping:

Automated crimping machines ensure secure and consistent terminal connections, which is critical for electrical reliability and long-term durability.

4. Tinning (Soldering)

Advanced Tinning Process:

We use automated tinning machines to apply solder to wire ends, enhancing conductivity and corrosion resistance.

5. Connector Insertion (Plastic Housing)

Automated Connector Assembly:

Machines automatically insert wires into plastic connectors, ensuring accurate pin placement and secure connections for a variety of harness configurations.

Advanced Machinery

10+ Automated Processing Machines:

We use cutting-edge automated machines that perform multiple functions with high precision and speed. These machines ensure consistent quality while reducing production time and human error.

2. Dedicated Automation Team

6 skilled operators and technicians:

Our dedicated automation team oversees the entire production process, ensuring smooth machine operation, fast troubleshooting, and continuous quality improvement.

3. Extensive Mold Inventory

Over 200 Precision Molds:

We have a large inventory of molds designed for a variety of wire types, terminal sizes, and connector configurations. This allows us to meet different customer requirements and quickly adapt to new project specifications.